Induction Heating Coil Design

It has been said that it is easy to design an induction heating coil that doesn’t work at all, and very difficult to design an induction heating coil that works really well. Fluxtrol has a reputation for solving the most complex coil design challenges with overwhelming success.

Fluxtrol focuses on designing induction heating coils that come as close as possible to achieving your ideal process. The Fluxtrol induction heating coil design team has many years of combined experience in modeling induction processes, designing induction heating coils, manufacturing induction heating coils, and operating induction heating systems.

Fluxtrol has also published numerous papers on induction heating coil design for different applications. Click here to view our technical library. Designing an optimal induction heating coil requires making an in-depth analysis of part heat treat specifications, production rates, operation sequences, material handling, induction system parameters, environmental conditions the induction heating coil will operate in and cooling system design. Read Article

The environmental conditions the induction heating coil will operate in is an often-overlooked factor in the coil development. Fluxtrol has developed induction heating coils for use in such diverse environments including with high pressure, low pressure, down-hole, submerged in a fluid, high vacuum, clean room, aggressive chemicals, explosion risks, exposure to molten metals, rugged manufacturing, field repair, high humidity, sterile environments for applications such as medical and food packaging, and radiative ones (both intensive thermal and ionizing). Understanding how to ensure reliable coil performance and preventing undesired interactions between components in these different applications can be the difference between success and failure in some challenging cases and Fluxtrol experts understand that custom solutions may be required for a given application.

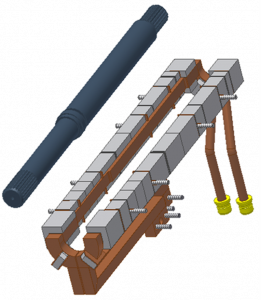

Fluxtrol uses the results from computer simulation for designers to create fully detailed engineering prints in the most current AutoCAD 2D and 3D drafting software. Fluxtrol can supply the customer with full sets of build prints, accurate detailed 3D models for insertion into your own designs or complete assembled details. Long considered the leading design and engineering firm in the industry, with the ability to prove design concepts in our lab, Fluxtrol has all of your design needs covered.

From concepts to completed parts, contact us for more information on induction heating coil design.