Soft Magnetic Composite (SMC) Materials

Welcome to Fluxtrol's Soft Magnetic Composite materials! Are you having a problem with heat gremlins? Click on a product below.

MACHINABLE SMCs

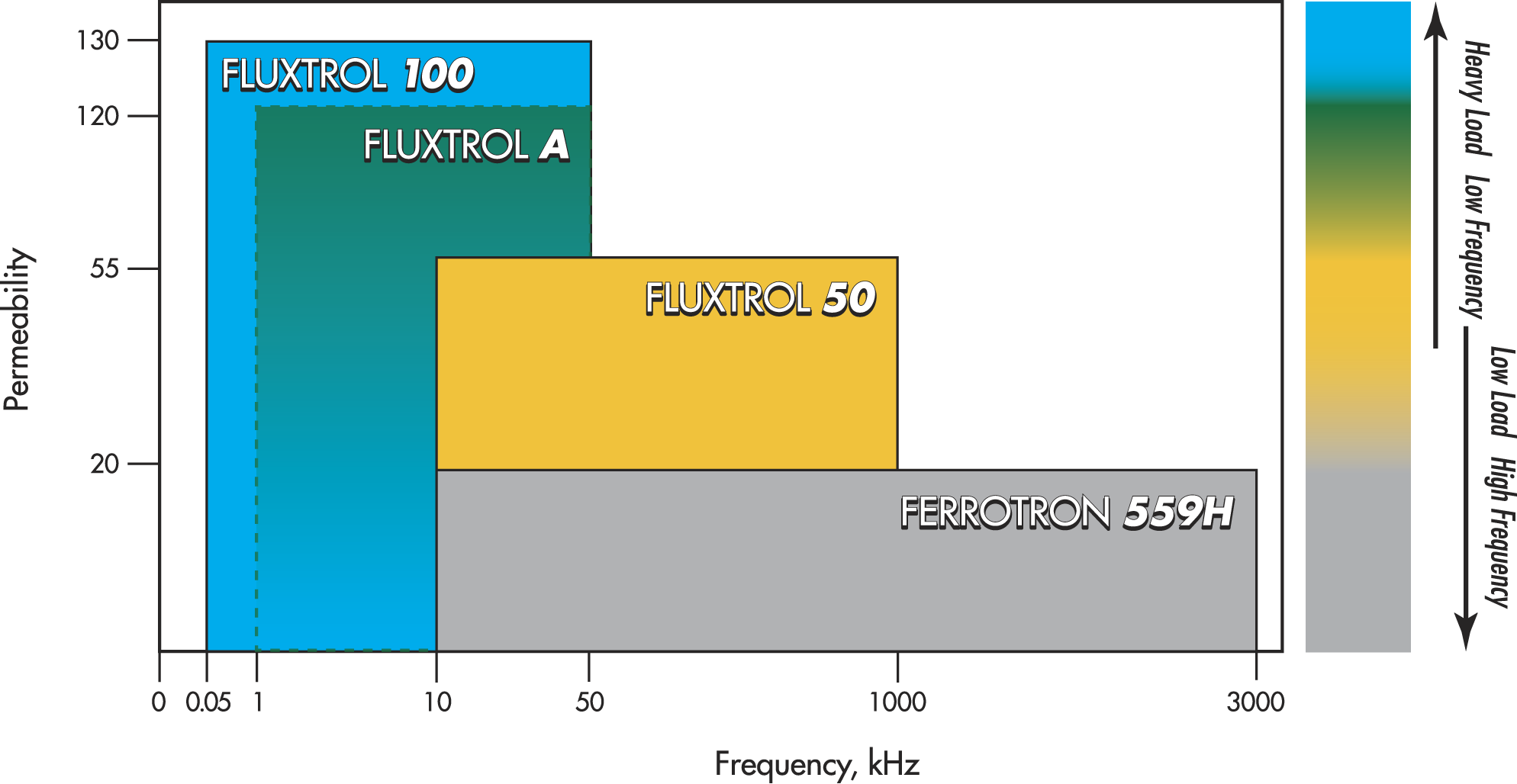

Fluxtrol 100

Frequency (Up to 50 kHz)

Excellent mechanical strength, machinability and thermal conductivity. Has the highest thermal conductivity, saturation flux density and flexural strength of the Fluxtrol family of materials.

Fluxtrol A

Frequency (Up to 100 kHz)

Highest maximum magnetic permeability and the lowest magnetic losses at low to intermediate frequencies in the Fluxtrol family of soft magnetic composites in the favorable magnetic direction.

Fluxtrol 50

Frequency (Up to 500 kHz)

Excellent performance over a wide range of frequencies. Material has good mechanical strength, machinability and thermal conductivity.

Fluxtrol 25

Frequency (Up to 500 kHz)

Good performance over a wide range of frequencies. Material has the best elasticity of Fluxtrol materials, excellent machinability and reasonable thermal conductivity.

Ferrotron 559H

Frequency (Up to 3000 kHz)

Almost constant magnetic permeability over a range of magnetic flux densities and frequencies. Material has good mechanical strength and thermal conductivity. Regarded by many to have the best machinability of the Fluxtrol family of materials.

Ferrotron 559H Original

Frequency (Up to 3000 kHz)

Similar to Ferrotron 559H standard, Original has nearly constant permeability over a wide range of flux densities and excellent machinability. When compared to Ferrotron 559H, Original has better mechanical strength, higher magnetic permeability, saturation flux density and thermal conductivity.

MOLDABLE (FORMABLE) SMCs

Alphaform LF

Frequency (1 - 80 kHz)

Formable soft magnetic composite developed on the basis of magnetic particles with a thermal-curing epoxy binder. This material may be used for quick and efficient installation to induction heating coils with low tolerances.

Alphaform MF

Frequency (10 - 1000 kHz)

Formable soft magnetic composite developed on the basis of magnetic particles with a thermal-curing epoxy binder. This material may be used for quick and efficient installation to induction heating coils with low tolerances.

Fluxtrol Selection Guide

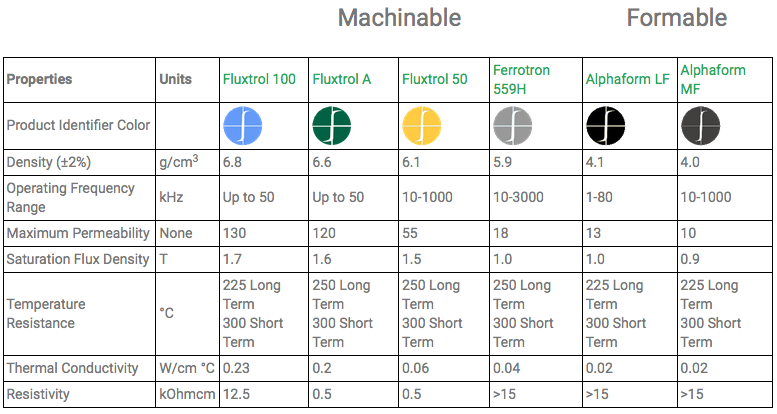

Fluxtrol Product Properties

| Machinable | Formable | |||||

|---|---|---|---|---|---|---|

| Properties | Fluxtrol 100 | Fluxtrol A | Fluxtrol 50 | Ferrotron 559H | Alphaform LF | Alphaform MF |

| Product Identifier Color | ||||||

| Density ±2% (g/cm3) | 6.8 | 6.7 | 6.2 | 5.9 | 4.1 | 4.0 |

| Operating Frequency Range (kHz) | Up to 50 | Up to 100 | Up to 500 | Up to 3000 | 1-80 | 10-1000 |

| Maximum Permeability | 132 | 142 | 55 | 18 | 13 | 10 |

| Saturation Flux Density (T) | 1.6 | 1.5 | 1.4 | 1.2 | 1.0 | 0.9 |

| Temperature Resistance (°C) | 225 Long Term 300 Short Term |

250 Long Term 300 Short Term |

250 Long Term 300 Short Term |

250 Long Term 300 Short Term |

225 Long Term 300 Short Term |

225 Long Term 300 Short Term |

| Thermal Conductivity (W/cm°C) | 0.28 | 0.10 | 0.084 | 0.055 | 0.02 | 0.02 |