Consulting Services

Magnetic Flux Control

Heat Treating and Melting

Emerging Technologies

Modeling and Optimization

On-Site Support

Personal Training

Centre for Induction Technology - Research and Development

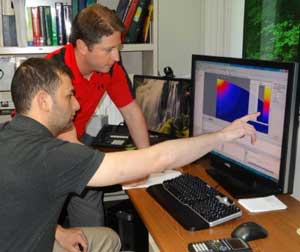

Research and Development is one of the core competencies of the Centre for Induction Technology. CIT’s R&D team offers a unique combination of practical and theoretical experience coupled with creativity and openness to new ideas.

The main cornerstones of our R&D are: deep understanding of induction heating and related phenomena, the use of an idea of Magnetic Flux Control and Computer Modeling.

To prove new concepts, we use our well-equipped laboratory with electrical, magnetic and thermal instrumentation in addition to induction heating power supplies with power ranging from 500 W to 50 kW and frequencies between 3 and 2000 kHz.

CIT has a long history of partnering with R&D groups from different universities, start-up companies and large, multinational corporations in exploration and development of new technologies and components. It allows us to resolve complex problems not only in traditional areas of Heat Treating and Melting but also in Emerging and Innovative Technologies such as in liquid food packaging, biomedical, aerospace and oil and gas industries, to name a few.