-

AlphaForm is soft and ductile at room temperature, but can be made even more flexible when heated with a heat gun or oven, not exceeding 140°F or 60°C as it may begin to cure and harden.

-

Place a strip of heavy duty aluminum foil (0.024 mm) along the working edge of the coil. This will provide a flat surface to form the AlphaForm against. Avoid using standard aluminum foil, (0.016 mm) as it may be more difficult to remove after curing. Also, remove all aluminum foil from the AlphaForm after curing.

-

Form the AlphaForm onto the coil and foil surface as desired. The AlphaForm might cool and become less pliable during forming. If it does, reheat the AlphaForm. AlphaForm can be repeatedly reheated, as long as the temperature does not exceed 140°F, or 60°C.

-

Wrap PTFE (polytetrafluoroethylene) thread seal tape around the AlphaForm to hold it tight against the coil. If not held in place, AlphaForm may shift slightly during curing. Use yellow gas line PTFE tape, which is thicker than white PTFE tape.

-

To cure the AlphaForm, place coil in an oven at 250°F (120°C) for one hour. Then increase the temperature to 375°F (190°C) for an additional hour.

-

Remove the PTFE tape from the coil. The bottom layer of PTFE tape will be fused onto the surface of the AlphaForm, but it will not affect the performance of the coil.

-

Remove the aluminum foil from the working surface of the coil. Carefully inspect the coil for any left behind foil fragments and remove them.

-

Put the induction heating coil into service. No machining is needed. However, AlphaForm can be machined or ground into a more desired shape if required.

-

For any additional information or help with your specific induction heating application, please contact Fluxtrol directly.

Note: There are many variables involved in an induction process. In order to utilize the fullest potential of our product, you must help narrow down the parameters you are operating with. Each grade of Fluxtrol material has its own distinctive properties that are beneficial to a certain range of electrical and design parameters. Contact Fluxtrol Inc. to receive more information about which material is right for you.

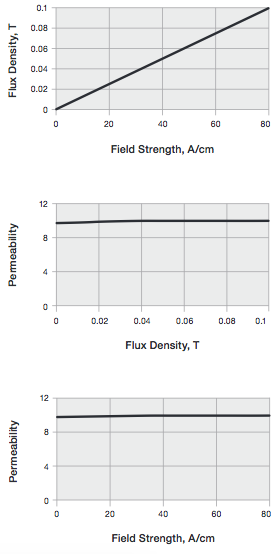

Alphaform MF

Alphaform MF