Information

Authors: Robert Cryderman, Finn Bamrud, Tareq Eddir, and Robert Goldstein

Publication: Journal of Materials Engineering and Performance, 2023

This article is an invited submission to the Journal of Materials Engineering and Performance selected from presentations at the 29th Heat Treating Society Conference and Exposition (Heat Treat 2017) held October 24–26, 2017, in Columbus, Ohio, and the 31st Heat Treating Society Conference and Exposition (Heat Treat 2021) held September 14-16, 2021, in St. Louis, Missouri. It has been expanded from the original presentation. The issue was organized by Robert Cryderman, Colorado School of Mines; Rob C. Goldstein, Fluxtrol; Collin A. Russell, Los Alamos National Laboratory; and John Tartaglia, Element Materials Technology.

Robert Cryderman and Finn Bamrud, Advanced Steel Processing and Products Research Center, Colorado School of Mines, Golden, CO; Tareq Eddir and Robert Goldstein, Fluxtrol, Auburn Heights, Auburn Hills, MI. Contact e-mail: rcryderm@mines.edu.

Download Full ArticleAbstract

Solid and hollow cylindrical specimens of ferrite–pearlite and austenitic stainless steel were induction heated at heating rates up to 600 °C·s−1 using a high precision DIL 805L dilatometer. High heating rates were attained for the magnetic state at temperatures below the curie (Ac2) temperature and reduced heating rates were observed for the non-magnetic austenite at temperatures above the Ac2. Heating the commonly used 4 mm diameter by 10 mm long specimens at rates above 50 °C·s−1 resulted in non-linear heating rates during transformation to austenite and large transient temperature variations along the specimen length. These limitations in heating rate and variances from ideal uniform heating lead to inaccurate measurement of the Ac1 temperature. Induction heating modeling showed that the specimen ends heated more slowly (colder ends) than the center for the magnetic ferrite structure and more rapidly (hotter ends) for the non-magnetic austenite structure. Changing the specimen design to a thin wall tube allowed faster heating rates and modified the pattern of temperature variations within the test sample. The response of selected specimen geometries to induction heating in the dilatometer was characterized by modeling and tests using multiple thermocouples to verify the models. The results demonstrated that the use of properly designed tubular test specimens can aid in more accurately determining the Ac1 transformation characteristics during heating at ultra-fast induction heating rates.

Introduction

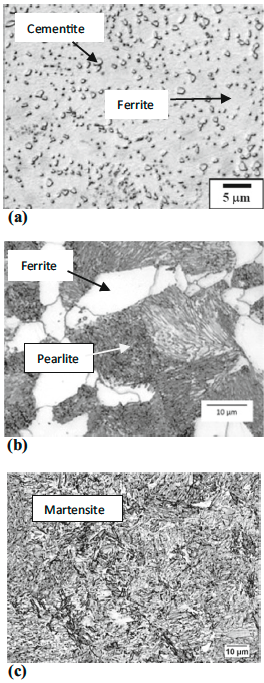

Induction hardening is widely used to produce high strength surface hardened parts such as axles, steering racks, and components for constant velocity joints (Ref 1). These parts are typically manufactured using carbon or low alloy steels containing 0.35 to 0.60 wt pct carbon (Ref 1). The initial microstructures can vary from soft, spheroidized cementite, to coarse ferrite–pearlite, to quenched and tempered martensite as illustrated in Fig. 1.

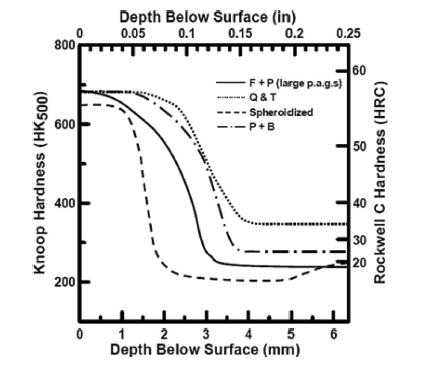

Surface hardening relies on the ability of induction heating to rapidly heat the part surface to a temperature above the Ac3 while limiting heating of the core to temperatures below the Ac1 (Ref 1). The hardening response of various 1541 steel microstructures consisting of ferrite and cementite to rapid induction hardening with a constant power input, heating time, and quench is illustrated in Fig. 2 (Ref 2). The main reason for the differences in hardening depth is the temperature and time required to transform the ferrite into austenite and diffuse carbon from the cementite into austenite, with coarser ferrite and cementite areas requiring higher temperatures or more time for diffusion (Ref 1, 3).

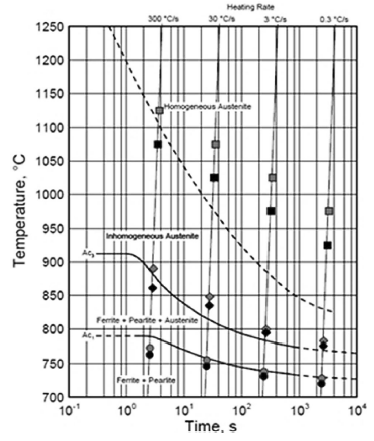

The influence of heating rate and peak temperature on the transformations during heating has been characterized in the literature as shown in Fig. 3 (Ref 4). As the heating rate increases, the Ac1 and Ac3 temperatures increase, and higher temperatures are needed to homogenize the carbon in the austenite. High speed dilatometry provides the opportunity to study the effects of induction heating rates and peak temperatures on the transformation to austenite and the resulting microstructures after quenching to form martensite. A DIL 805L quenching dilatometer relies on induction heating and was used in this study (Ref 5). A commonly used 4 mm diameter by 10 mm long cylindrical specimen was selected as the starting point for this study and the effects of specimen diameter, length, and wall thickness were evaluated. Magnetic O1 tool steel and non-magnetic stainless steel were incorporated in the study to assess the heating response of ferrite and austenite. Commercial induction hardening heating rates are often 1000 °C·s−1 and can be higher. The purpose of this study is to determine what changes in specimen design can be made to increase the heating rate and assess the effect of specimen design on gradients in temperature when using the DIL 805L dilatometer for rapid heating. Cylindrical and tubular specimens were selected for study vs flat specimens to minimize the complexity that comes from 3D vs 2D behavior. Resistance heating via a Gleeble® type system is a possible alternative that offers very high heating rates, but also has challenges of measuring and controlling temperature gradients.

Experimental

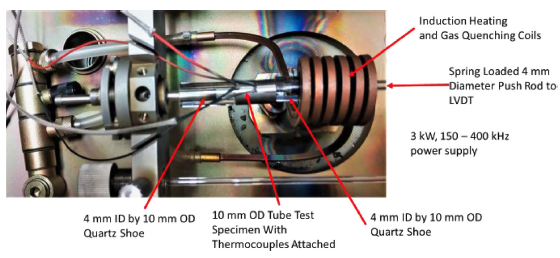

The testing device being used to study non-equilibrium transformation dynamics in this study is a TA Instruments DIL 805L dilatometer shown in Fig. 4 (Ref 5). The DIL 805L unit heats in vacuum and uses a 3 kW, 150-400 kHz induction heating power supply for heating followed by helium inert gas quenching. The coil consists of 6 turns for a total length of 26.8 mm long and has an inner diameter of 15.4 mm. Temperatures are monitored and controlled during the process by using a thermocouple welded to the specimen surface at the center. For this study, additional thermocouples were attached on the cylindrical surface near the ends of a 1045 specimen. Quartz push rods, 4 mm in diameter, were used to contact the specimen ends for specimens with an internal diameter (ID) smaller than 4 mm. For larger specimen diameters, a short section of the 4 mm quartz tube was welded to the inside of tubular quartz "shoes" with an ID of 4 mm and an outer diameter (OD) of 10 mm. These shoes were slipped onto the ends of the 4 mm diameter push rods to support the specimens and allow measurement of dilation. The test specimens used in this study are summarized in Table 1.

| Steel | Shape | OD, mm | Length, mm | Wall, mm |

|---|---|---|---|---|

| O1 | Solid | 1.5 | 10 | ... |

| O1 | Solid | 2.0 | 10 | ... |

| O1 | Solid | 3.0 | 10 | ... |

| O1 | Solid | 4.0 | 10 | ... |

| 1045 | Solid | 4.0 | 10 | ... |

| 304 SS | Tube | 3.18 | 10 | 0.89 |

| 304 SS | Tube | 4.0 | 10 | 1.0 |

| 304 SS | Tube | 6.0 | 10 | 1.0 |

| 316 SS | Tube | 8.0 | 7.5 | 1.0 |

| 316 SS | Tube | 10.0 | 15 | 1.0 |

| 316 SS | Tube | 10.0 | 7.5 | 1.0 |

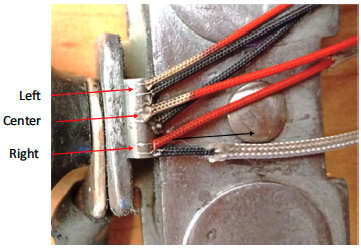

Magnetic O1 tool steel cylinders (O1) and non-magnetic austenitic 304 or 316 stainless steel tubes (SS) in diameters up to the anticipated limit for the 15.4 mm inner diameter coil size were used to evaluate the effects of specimen design on maximum heating rates and temperature variations. The O1 steel solid rods and the SS tubes were commercially available in the indicated diameters and were cut to the indicated specimen lengths. One additional material, 1045 steel specimen, was machined from a larger bar and was included to illustrate the effects of non-uniform heating at high rates on dilation and measured transformation temperature. The 1045 specimen was instrumented with thermocouples attached near both ends of the specimen as well as the center as shown in Fig. 5. DIL 805L standard data outputs including temperature at the center of the specimen, specimen dilation, and percent of maximum available induction heating power were recorded simultaneously as a function of time.

Flux 2D software (Ref 6) was used for electromagnetic and thermal simulation to understand the temperature distributions for the different specimen geometries, material properties, and heating rates. 1045 and stainless steel material properties were used to compare heating differences between magnetic and non-magnetic steels. Temperature data from the center of the specimen length (T. C.) and 1 mm from the end was collected for comparison. Current supply was controlled to achieve the desired heating rates at the T. C. Additionally, temperature contours, maximum temperature, minimum temperature, average temperature, temperature gradient, and electrical parameter data were collected from the models for comparing the different simulations.

Results - Dilatometer Tests

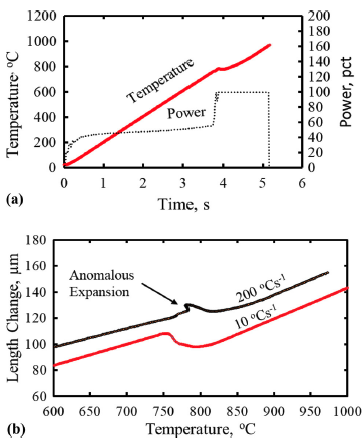

A solid 4 mm diameter by 10 mm long cylinder of the 1045 steel was heated at a programmed rate of 200 °C·s−1 and the time-temperature data shown in Fig. 6(a). indicate that a 200 °C·s−1 heating rate was achieved for both ferrite–pearlite and austenite temperature ranges. During the period where the transformation from ferrite–pearlite to austenite occurred, the programmed heating rate was not maintained as the induction heating unit lacked sufficient power to overcome the increased energy requirement for the transformation to austenite (Ref 7).

Figure 6(b) shows the dilation versus temperature for heating at 200 °C·s−1 as compared to heating at 10 °C·s−1 showing an increased Ac1 temperature which is consistent with published data (Ref 3, 8). An anomalous expansion at the Ac1 temperature with the faster heating rate prevents accurate determination of the Ac1 temperature and as characterized below, is the result of non-uniform temperature gradients with the rapid heating rate.

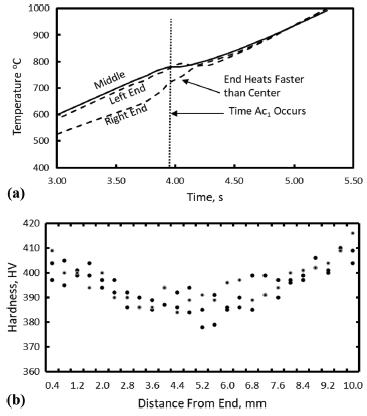

The transient temperature gradients are illustrated in Fig. 7. In Fig. 7(a) thermocouples were attached near the specimen ends (Fig. 5) as well as at the center of the specimen. At temperatures below the Ac1 temperature, the ends were clearly colder than the center. The difference in the temperature curves between the right and left ends of the specimen are due to small errors in the positioning of the thermocouples as shown in Fig. 5. At the Ac1 temperature, the heating rate at the center declined as the center transformed to non-magnetic austenite while the magnetic ferrite– pearlite ends continued to heat at a more rapid rate. Consequently, the measured dilation increased as the cold ends heated more quickly leading to the apparent expansion shown in Fig. 6(b).

To verify the occurrence of the cold ends, a 1045 steel specimen was first austenitized and quenched to martensite and then heated at 200 °C·s−1 to 740 °C and immediately helium quenched. Hardness tests along the length of the specimen, Fig. 7(b) show that there was less tempering (higher hardness) on the ends as a consequence of the lower peak heating temperature. The large end to center temperature gradients make it difficult to accurately determine the Ac1 temperature and the rate of transformation to austenite at higher temperatures up to the Ac3. The issue of non-uniform temperature increases as the heating rate is increased as shown in Fig. 6(b).

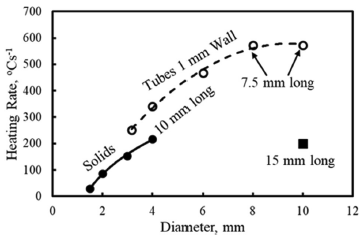

It is well known that non-magnetic austenite requires more induction heating power than magnetic ferrite to achieve the same heating rates (Ref 1). Solid test specimens of ASTM A681 O1 tool steel, 10 mm long, were heated with a programmed heating rate of 500 °C·s−1. The maximum heating rates actually achieved in the ferritic range and austenitic range for the different specimen diameters are summarized in Table 2. The data clearly show that the heating rate in the non-magnetic austenite range at high temperatures is slower than the heating rate for magnetic ferrite at lower temperatures. Also, the heating rates for austenite increased as the specimen diameter increased from 1.5 to 4 mm, indicating better coupling with the induction field. There was no consistent change in the heating rate of ferrite with the increasing diameter.

| Specimen diameter, mm | Ferrite heating rate, 200 to 700 °C | Austenite heating rate, 850 to 1,000 °C |

|---|---|---|

| 1.5 | 468 | 27 |

| 2.0 | 534 | 84 |

| 3.0 | 477 | 145 |

| 4.0 | 457 | 190 |

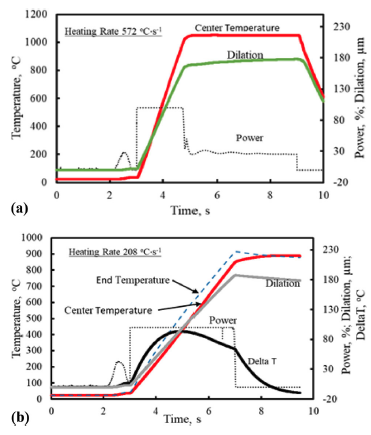

Based on previous experience it was decided to conduct heating rate tests in the dilatometer using SS in a variety of specimen designs within the coil capability and then use a model to examine the expected temperature variations. Specimens 10 mm long were cut from the 3.1 mm, 4 mm, and 6 mm diameter type 304 stainless steel tubes and heated at maximum power in the dilatometer to determine the maximum heating rate at the center of the specimens. The results are presented in Fig. 8 along with the results for the cylindrical O1 steel specimens heated at temperatures above the Ac3 temperature. At 4 mm diameter, the maximum heating rate for the austenitic tubes was about 125 °C·s−1 higher than the limit for the solid cylinders. Also, the heating rate increased with the tube diameter to about 480 °C·s−1 for the 6 mm diameter stainless tube. The increased heating rate at larger specimen diameters is likely due to the increased magnetic flux near the inner surface of the coil. (Ref 1) Specimens of 8 and 10 mmaustenitic 316 stainless steel tubes cut to 7.5 mm long and heated with the maximum power resulted in a maximum heating rate of 572 °C·s−1 for both specimens diameters. These results indicate that the maximum heating capability was achieved at the 7.5 mm specimen length. A further test using a 15 mm long 10 mm diameter tube resulted in a lower heating rate of about 200 °C·s−1 confirming that the power input limit was exceeded.

Results - Model Calculations

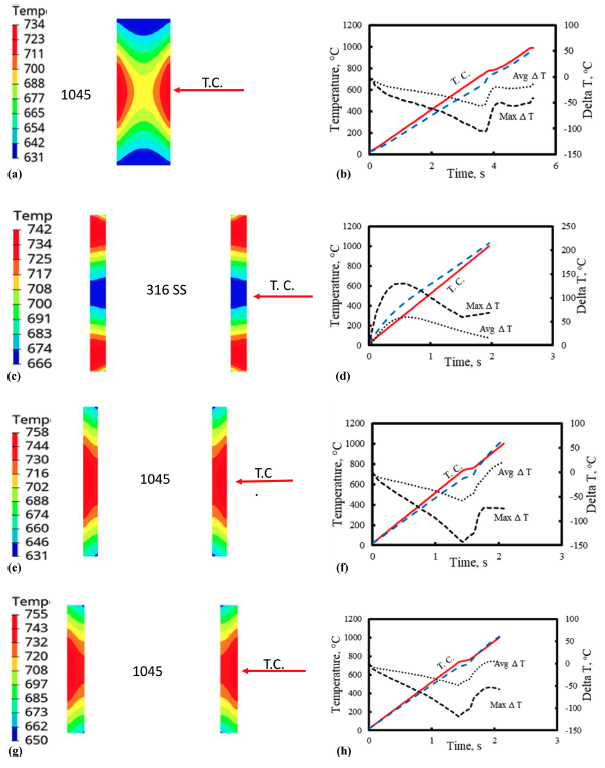

The models were used to calculate temperature distributions in several specimen types during heating. A temperature map for the reference 4 mm diameter by 10 mm long 1045 solid steel specimen at an average temperature of 720 °C for the maximum heating rate (200 °C·s−1) is shown in Fig. 9(a). The chart in Fig. 9(b) shows the change of temperature with time at the center thermocouple (T. C.) location and 1 mm from the end of the specimen. The maximum and average differences in temperature relative to the center thermocouple are shown as Max and Avg delta T, respectively. The Avg delta T is of importance with respect to measuring the dilation over the full specimen volume. For example, in Fig. 9(a) the average temperature (delta T in Fig. 9(b)) was 56 °C lower than the temperature measured at the specimen center just before reaching the Ac1 temperature—so the measured Ac1 temperature reading could be as much as 56 °C higher than the actual.

It should be noted that the data for the 1045 tubular specimens in Fig. 9(f) and (h) reflect a higher heating rate of about 500 °C·s−1 as compared to the 200 °C·s−1 limit for the solid specimen in Fig. 9(b) and the time scales were adjusted accordingly.

The color maps, in Fig. 9(a), (b), (e), (f), (g) and (h) show that during heating the magnetic ferrite-pearlite microstructure 1045 steel to the Ac1 temperature, the specimen was hottest at the center thermocouple location and coldest at the ends. The delta T values for the 1045 steel specimens increased progressively with time up until the beginning of transformation to austenite and then declined to minimal values at the completion of the transformation.

By contrast, during heating of the 10 mm diameter by 10 mm long non-magnetic austenitic stainless-steel specimen, the temperature map and chart in Fig. 9(c) and (d) clearly show that the specimen ends were hotter than the temperature indicated by the center thermocouple. The difference in temperature first increased with time and then decreased at longer times and higher average temperatures. It should be noted that the delta T curves for the stainless-steel specimen in Fig. 9(c) and (d) are all positive whereas they are negative for the 1045 steel specimens. The difference is believed to be the result of the influence of the magnetic properties of the 1045 steel on the magnetic flux field at the specimen ends. (Ref 9)

The temperature model for the tubular 10 mm diameter by 7.5 mm long magnetic, ferrite pearlite 1045 steel (Fig. 9g and h) shows that the center heats faster than the ends, but there is less gradient from the outside to the inside as compared to the solid specimen in Fig. 9(a) and (b). Also, the maximum temperature gradient was lower for the 7.5 mm long specimen (Fig. 9g and h) as compared to the 10 mm long specimen (Fig. 9e and f). This simulation assumed a fixed heating rate of 500 °C·s−1 for the 7.5 mm long specimen and that this rate was maintained in the austenite region after the transformation from ferrite-pearlite. Presumably, once the 1045 steel is heated beyond the Ac1 temperature where austenite begins to form and progressively increases up to the Ac3 temperature, the specimen ends would heat faster than the center as was observed for the austenitic stainless-steel specimens.

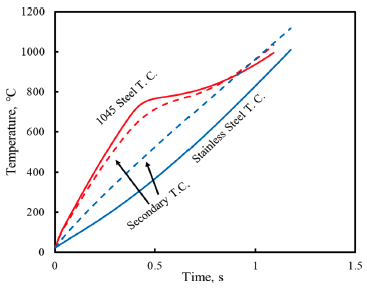

For illustration, the calculated heating curves for 10 mm diameter by 10 mm long tubular specimens of the 1045 steel and the austenitic stainless steel heated with an assumed fixed coil current of 225 amperes are compared in Fig. 10. The temperature curves reflect the negative temperature variation compared to the center thermocouple for the 1045 steel and the positive temperature variation compared to the center thermocouple for the stainless steel. The curve for the 1045 steel indicates that heating rates faster than 500 °C·s−1 are possible for the magnetic ferrite pearlite structure, but not during the transformation to austenite.

Based on the earlier test results and guided by the modeling, it was decided to use a 7.5 mm long by 10 mm diameter tube with a 1.0 mm wall thickness for tests on the dilatometer. Preliminary tests were conducted on austenitic 10 mm diameter stainless tube specimens at both the 7.5 and 15 mm length. The test results are shown in Fig. 11. The test results verified that a heating rate of 572 °C·s−1 is possible for the 7.5 mm long specimen, but the heating rate dropped to 208 °C·s−1 as the specimen length was increased to 15 mm.

Conclusions

From induction modeling and verification tests conducted in the TA DIL 805L dilatometer it has been shown that heating rates for 1045 steel can be increased with the existing induction heating system by changing from a solid cylindrical specimen to a tubular specimen.

- By changing from a 4 mm diameter by 10 mm long solid specimen to a shorter 7.5 mm long by 10 mm diameter by 1 mm wall thickness specimen the maximum heating rate for austenite was increased from 200 to 572 °C·s−1

- Temperatures at the ends of the specimens were colder than the center when heating magnetic ferrite pearlite microstructures and hotter than the center when heating non-magnetic austenite

- Heating rates for magnetic ferrite pearlite microstructures at maximum power were higher than those that could be achieved for non-magnetic austenite.

- Reducing tubular specimen length below 10 mm allowed higher heating rates and reduced the temperature variation.

- For the 1045 steel specimens, tested and modeled, temperature variations (delta T) along the specimen length persisted at high heating rates that resulted in overestimating the Ac1 temperature by up to 57 °C. Shorter 7.5 mm long tubular specimens reduced the maximum average delta T to 48 °C.

Acknowledgements

The authors acknowledge the support of the corporate sponsors of the Advanced Steel Processing and Products Research Center, an industry/university cooperative research center at the Colorado School of Mines for the experimental work and the support of Fluxtrol. Inc for the temperature modeling. Thanks also to Michael Sanders at CSM for welding the quartz shoes used in the experiments.

References

[1] V. Rudnev, G. Fett, A. Griebel, and J. Tartaglia, Principles of Induction Hardening and Inspection. ASM Handbook vol 4C Induction Heating and Heat Treatment. pp 58-86 (2014)

[2] J. Coryell, The Effect of Induction Hardening on the Mechanical Properties of Steel with Controlled Prior Microstuctures. M. S. Thesis, Colorado School of Mines, Golden, Colorado (2004)

[3] H. Osborn, Metal Progress Datasheet. P.153 (1975)

[4] K. Clarke, The Effect of Heating Rate and Microstructural Scale on Austenite Formation, Austenite Homogenization, and As-quenched Microstructure in Three Induction Hardenable Steels, PhD Thesis, Colorado School of Mines, Golden, Colorado (2008)

[5] DIL 805L Dilatometer, TA Instruments, https://www.tainstruments.com/dil-805l-quenching-dilatomers/

[6] Altair, "Hyperworks," www.altairhyperworks.com

[7] R. Goldstein, T. Eddir, E. Buchner, R. Cryderman, A. Banka, and A. Senita, Modeling of Temperature Gradients During Short Time Dilatometry Testing, J. Mater. Eng. Perform., 2020 https://doi.org/10.1007/s11665-020-04862-2

[8] S. Semiatin and D. Stutz, Induction Heat Treatment of Steel, ASM International, 1986

[9] V. Rudnev, D. Loveless, and R. Cook, Handbook of Induction Heating, Theoretical Background, July 2017, https://www.routledgehandbooks.com/https://doi.org/10.1201/9781315117485-3

[10] R. Cryderman, F. Bamrud, R. Goldstein, and T. Eddir, Heat Treat 2021: Proceedings of the 31st ASM Heat Treating Society Conference, September 14–16, 2021 America s Center, St. Louis, Missouri, USA DOI: https://doi.org/10.31399/asm.cp.ht2021p0138

Publisher’s Note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Corresponding Author

Sean Michael Muyskens can be contacted at: smmuyskens@fluxtrol.com

If you have more questions, require service or just need general information, we are here to help.

Our knowledgeable Customer Service team is available during business hours to answer your questions in regard to Fluxtrol product, pricing, ordering and other information. If you have technical questions about induction heating, material properties, our engineering and educational services, please contact our experts by phone, e-mail or mail.

Fluxtrol Inc.

1388 Atlantic Boulevard,

Auburn Hills, MI 48326

Telephone: +1-800-224-5522

Outside USA: 1-248-393-2000

FAX: +1-248-393-0277