Information

Authors: Robert Goldstein

Location/Venue: ASM HTS 17 Cleveland, OH

Topic: Heat Treating

Overview

- Advantages of Induction Heating Compared to Other Methods

- How induction heating works

- Applications of Induction Heat Treating

- Conclusions

Specific Features of Induction Heating

- Heat generation occurs inside the part

- Heating is contactless

- Method can provide very high power densities

- Heating may be highly selective in the depth and along the surface

- Any processing atmosphere (air, protective gas, vacuum)

- Very high temperatures may be created

- NASA currently using induction to test survivability of NTP fuel elements at 5000 F to ensure safety for a trip to Mars – NTREES Program

What is Induction Heating?

Induction Heating is a Contactless Heating Method of bodies, which absorb energy from an Alternating Magnetic Field, generated by Induction Heating Coil (Inductor).

There are two mechanisms of energy absorption:

- generation of close-loop (eddy) currents inside the body which cause heating due to electrical resistance of the body material

- hysteresis heating (for magnetic materials ONLY!) due to a friction of magnetic micro volumes (domains), which rotate following orientation of external magnetic field

Mutually Coupled Phenomena in Induction Heating Process

Principle of Induction Heating

Chain of phenomena:

- Power supply delivers current (I1) to induction heating coil

- Coil currents (ampere-turns) generate magnetic field. Lines of field are always closed (law of nature!) and each line goes around the current source – coil turns and workpiece

- Alternating magnetic field flowing through the part cross-section (coupled to the part) induces voltage in the part

- Induced voltage creates eddy currents (I2) in the part flowing in direction opposite to the coil current where possible

- Eddy currents generate heat in the part

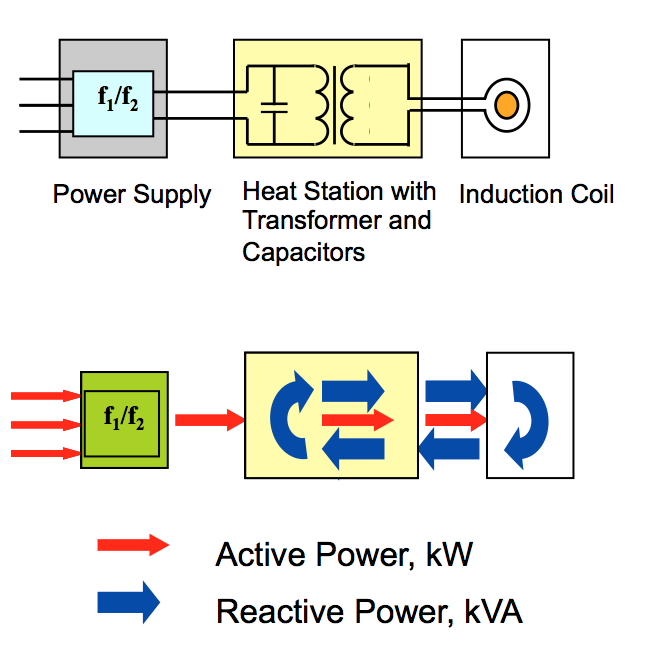

Power Flow in Induction Heating Installations

Alternating current changes direction twice during each frequency cycle. If frequency is 1kHz, current changes direction 2000 times in a second.

A product of current and voltage gives the value of instantaneous power (p = i x u), which oscillates between the power supply and the coil. We can say that power is being partially absorbed (Active Power) and partially reflected (Reactive Power) by the coil. Capacitor battery is used to unload the generator from the reactive power. Capacitors receive reactive power from the coil and send it back to the coil supporting oscillations.

A circuit “coil-transformer-capacitors” is called Resonant or Tank Circuit.

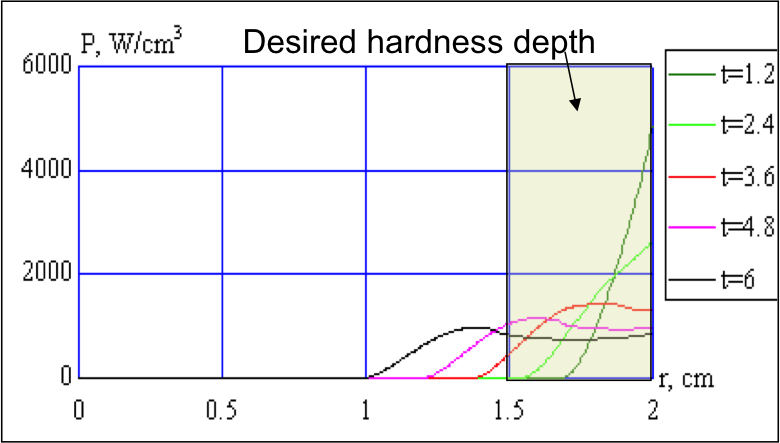

Power Density Curves for Induction Surface Hardening Process

Effectiveness of induction surface hardening strongly depends on frequency selection.

At the end of heating cycle when utilizing the optimal frequency the maximum value of power density must be just beyond the required hardness depth (5 mm in the case on right).

For simple cases of flat and round pieces and traditional steels, there are graphs and formulas for frequency selection. However, computer simulation is a much more powerful, universal and accurate design tool.

Part diameter 1.6” (4 cm), frequency 4 kHz, Required hardness depth – 0.2” (5 mm)

ELTA simulation program

Recommended Frequency for Different Case Depths

Optimal frequency corresponds to Case Depth = 0.5 δ

Good frequency range corresponds to 0.3 δ < Case Depth < 1 δ

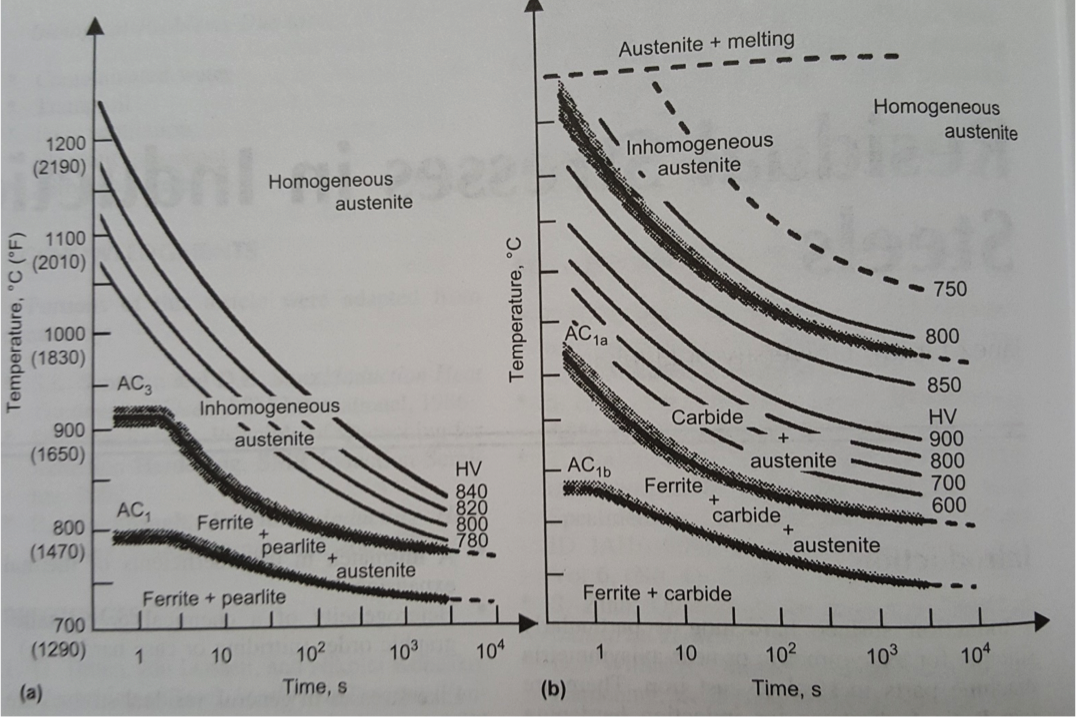

Temperature Evolution During an Induction Hardening Process

Compared to furnace heating induction hardening provides much faster heating when optimal frequency is used.

Using direct flame method, in order to achieve required temperature at a needed depth, surface must be strongly overheated or even melted.

When using induction, due to the cold core, surface compressive residual stresses are much higher than for through heated, furnace hardened components

Effect of Short Time Heat Treatment on Transformation Temperature

Hypoeutectiod steel CK45 left, hypereutectoid steel 100Cr6 right

Source – ASM Handbook Volume 4C – Grum

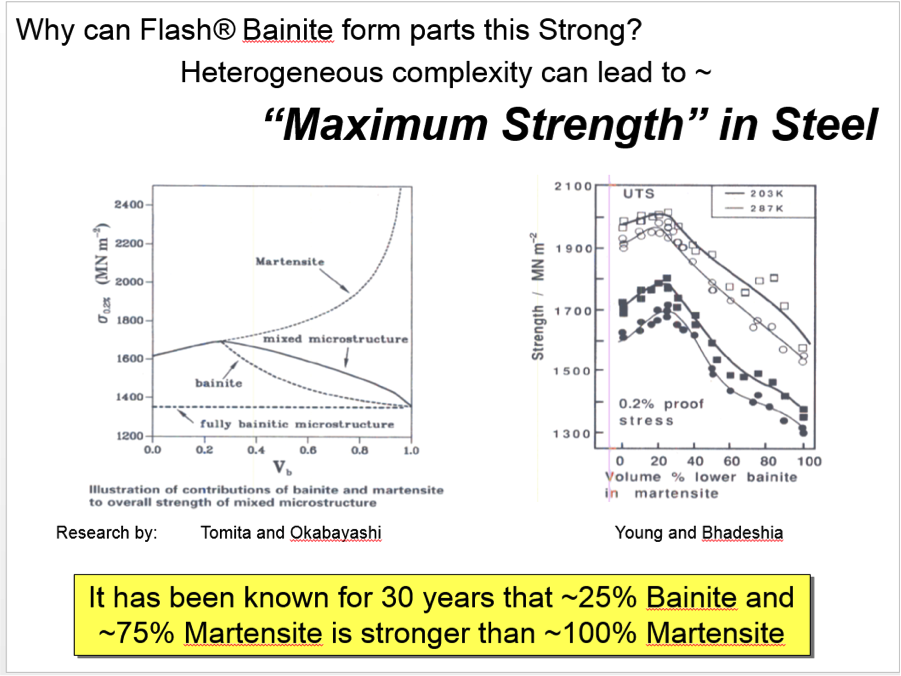

Improved Mechanical Properties Possible when Using Non-Equilibrium Structures

Courtesy of SFP Works dba FlashBainite

Cold Formed AHSS Components

Courtesy of SFP Works dba FlashBainite

Able to Produce More Cost Effectively Complex Structures

Courtesy of SFP Works dba FlashBainite

Specific Features of Induction Heating Ctd.

- Stand-by losses of equipment are very low

- Fast start-up (instantaneous in most cases)

- Heating may be easily programmed and automated

- No contamination of treated material may be provided (important for medical material, semiconductors, ultrapure metals, etc.!)

- Environmentally friendly

- If electricity is generated by renewable resources, zero greenhouse gas process!

Advantages of Induction Heating

- Short heating cycles and high production rates

- Electromagnetic forces can be used in combination with heating to stir or contain molten metal

- Better metallurgical results due to fast and clean heating

- Energy savings due to selectivity and high efficiency

- Good control and repeatability

- Minimal or no surface oxidation and decarburization

- Lower distortions for surface or local hardening

- Favorable for industrial environment (in-line heating, no pollution, “push button” performance)

- Some processes may not be accomplished other than by induction

Comparison of Through and Induction Hardened Bending Fatigue | Source – ASM Handbook Volume 4C – Grum

Comparison of Through, Case and Induction Hardened Fatigue Life for Transmission Shafts | Source – ASM Handbook Volume 4C – Grum

Major Applications of Induction Heating

- Melting

- Continuous casting

- Investment Casting

- Galvanizing

- Forging & Forming

- Preheating

- Welding

- Shrink-fitting

- Hard facing/coating

- Bonding

- Brazing

- Heat Treatment

- Plasma Processing

Where is Induction Used?

- Automotive

- Off-Highway/Construction

- Aerospace

- Metallurgical Plants

- Oil & Gas Component Manufacturing

- Special Applications

Vehicle Induction Heat Treating

- Engine

- Axles

- Bearing Assemblies

- Drivetrain Assemblies

- Steering Components

- Structural Components

- Fasteners

- Gears

- Etc.

Strip Heating – AjaxTocco Magnethermic

Large Gear Heat Treatment – Courtesy of Inductoheat

Local Hardening

Automotive Wheel Hub Heating time 5 seconds

Scan Hardening of an Axle Shaft

Typical Axle Heat Treat Pattern and Cut Results

Conclusions

- Induction heating is a widely used technology for heat treating

- Despite the presentation contains only steel components, any conductive or magnetic material can be inductively heated

- Induction heating has advantages over other technologies due to its environmental friendliness, ease of in-line incorporation, high available volumetric power densities and ability to control locally the distribution of heat and power

Acknowledgements

Many of the slides in this presentation were taken from the “Basics of Induction Heating Parts I & II” prepared by Dr. Valentin Nemkov (www.fluxtrol.com)

Most of the videos are Courtesy of Inductoheat (www.inductoheat.com) and other Inductotherm group companies (www.inductotherm.com)

If you have more questions, require service or just need general information, we are here to help.

Our knowledgeable Customer Service team is available during business hours to answer your questions in regard to Fluxtrol product, pricing, ordering and other information. If you have technical questions about induction heating, material properties, our engineering and educational services, please contact our experts by phone, e-mail or mail.

Fluxtrol Inc.

1388 Atlantic Boulevard,

Auburn Hills, MI 48326

Telephone: +1-800-224-5522

Outside USA: 1-248-393-2000

FAX: +1-248-393-0277