Information

Authors: Robert Goldstein

Location/Venue: 2017 Colorado School of Mines

Overview

- What Is Induction Heating?

- Applications of Induction Heating

- Case Stories

- Additive Manufacturing

- Cancer Treatment

- Organ Transplantation

- Deep Space Exploration

- Conclusions

What is Induction Heating?

Induction Heating is a Contactless Heating Method of bodies, which absorb energy from an Alternating Magnetic Field, generated by Induction Coil (Inductor)

There are two mechanisms of energy absorption:

- generation of close-loop (eddy) currents inside the body which cause heating due to electrical resistance of the body material

- hysteresis heating (for magnetic materials ONLY!) due to a friction of magnetic micro volumes (domains), which rotate following orientation of external magnetic field

Principle of Induction Heating

Chain of phenomena:

- Power supply delivers current (I1) to induction coil

- Coil currents (ampere-turns) generate magnetic field. Lines of field are always closed (law of nature!) and each line goes around the current source - coil turns and workpiece

- Alternating magnetic field flowing through the part cross-section (coupled to the part) induces voltage in the part

- Induced voltage creates eddy currents (I2) in the part flowing in direction opposite to the coil current where possible

- Eddy currents generate heat in the part

Mutually Coupled Phenomena in Induction Heating Process

Specific Features of Induction Heating

- Heat generation occurs inside the part

- Heating is contactless

- Method can provide very high power densities

- Heating may be highly selective in the depth and along the surface

- Any processing atmosphere (air, protective gas, vacuum)

- Very high temperatures may be created

Specific Features of Induction Heating Continued

- Stand-by losses of equipment are very low

- Fast start-up (instantaneous in most cases)

- Heating may be easily programmed and automated

- No contamination of treated material may be provided (important for medical material, semiconductors, ultrapure metals, etc.!)

- Environmentally friendly

- If electricity is generated by renewable resources, zero greenhouse gas process!

Where is Induction Used?

- Automotive

- Off-Highway/Construction

- Aerospace

- Metallurgical Plants

- Oil & Gas Component Manufacturing

- Food/Drug Packaging

- High Tech Applications

- Focus of today's talk

Major Applications of Induction Heating of Steel

- Melting

- Continuous Casting

- Investment Casting

- Galvanizing

- Forging & Forming

- Preheating

- Welding

- Shrink-fitting

- Hard facing/coating

- Bonding

- Brazing

- Heat Treatment

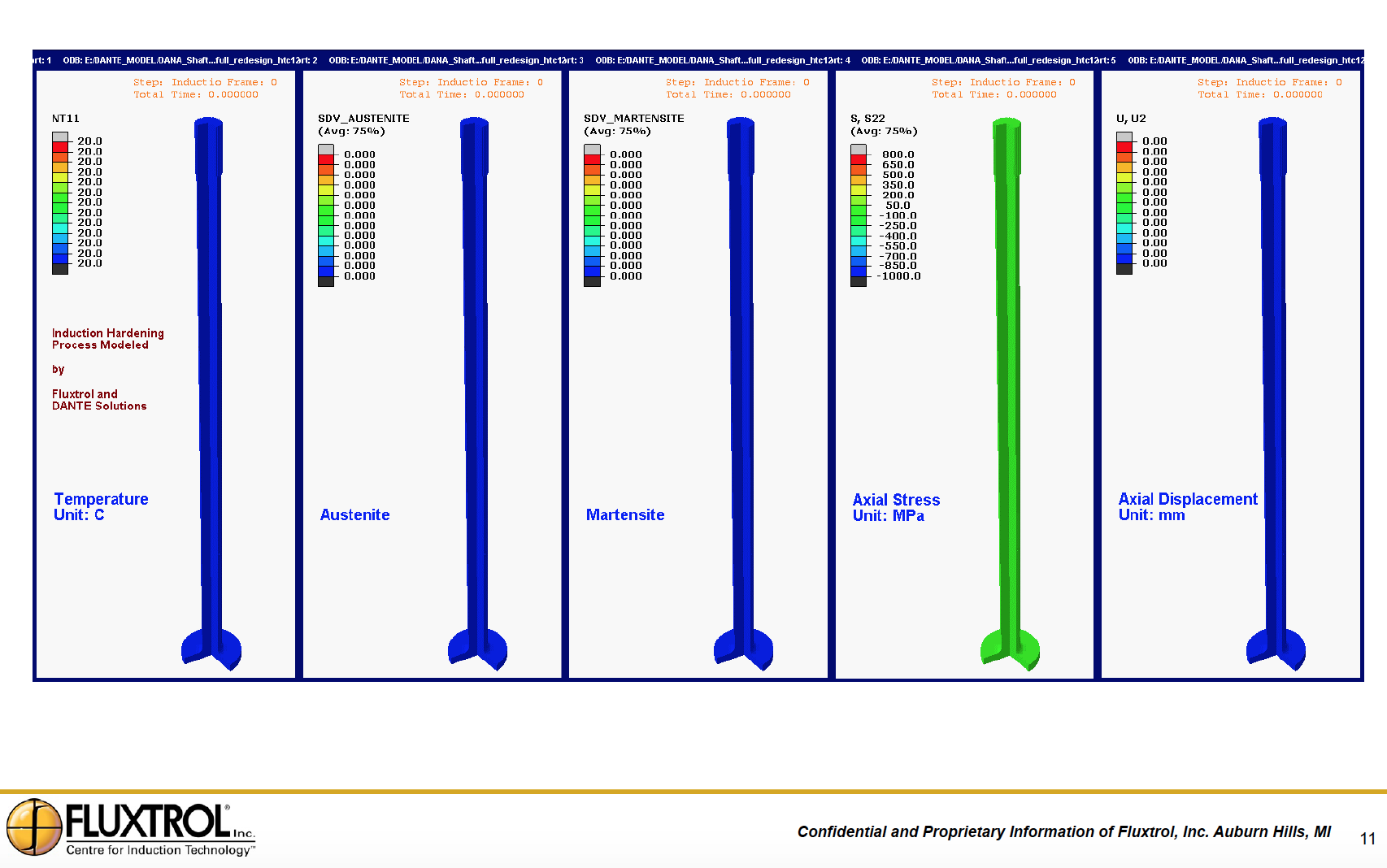

Axle Scan Hardening Model

More Advanced Model

Real Axle Scan Hardening Process

What is Additive Manufacturing?

-

“Additive Manufacturing (AM) is an appropriate name to describe the technologies that build 3D objects by adding layer-upon-layer of material, whether the material is plastic, metal, concrete or one day…..human tissue.” www.additivemanufacturing.com

For today’s talk, we will limit ourselves to metallic components used for high temperature, high performance applications

- Layered Manufacturing

- Additive Fabrication

Applications of Induction Heating in Additive Manufacturing

- High Quality Powder Production

- Primary Heat Source for Applications such as Hard Facing

- Heating for Control of Residual Stresses during AM Process

- Post-AM Heat Treatments

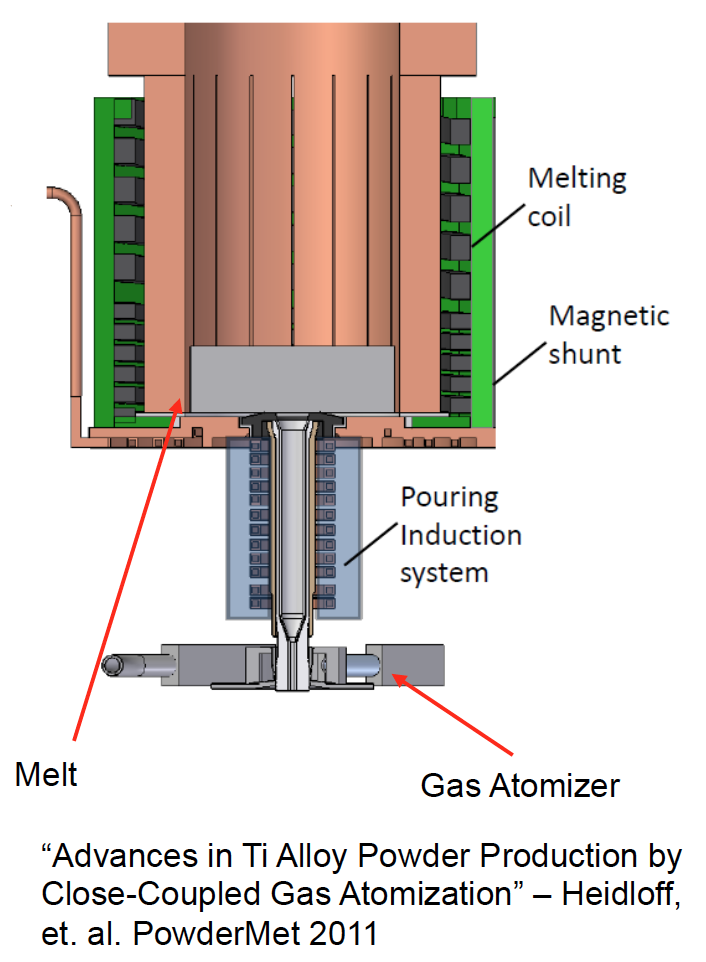

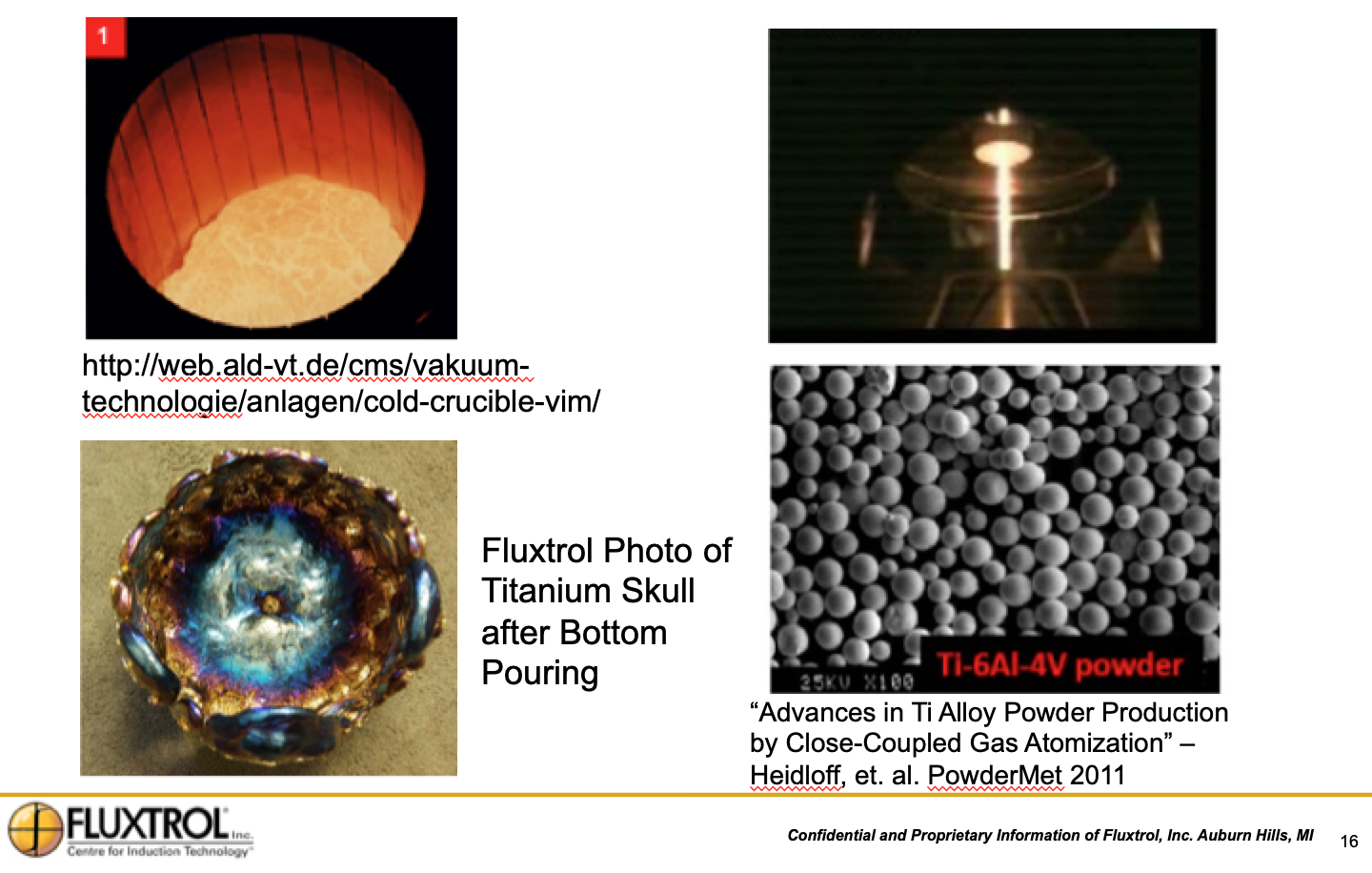

High Quality Powder Production

- Additive manufacturing requires precise particle size distributions with precise chemistries

- Small levels of impurities in the powder can have significant adverse effects on the final component properties

- Due to this, cold crucible melting is often used for titanium, titanium alloy and nickel based alloy powder production

- In cold crucible melting, a water cooled crucible is the only thing directly exposed to the metal, which forms a frozen skull with liquid metal inside preventing contamination of the melt allowing for precise chemistry

- Several other contactless inductive melting methods are use powder production

Process Images

Induction Hard Facing

- Often used to simultaneously improve corrosion and wear resistance of massive components

- A powder made of a high value material is applied to the surface of a large component made of less expensive material or material with desired bulk properties

- The surface of the less expensive material is heated using induction heating, melting the powder applied to the surface

- Melting from the base metal out significantly improves the product quality and consistency compared to surface energy deposition and enables formation of thicker layers protective layers

Cancer Treatment

- Proper delivery of elevated temperatures (hyperthermia) has been proven to have beneficial effect in the treatment of cancer, especially when combined with radiation and/or chemotherapy

- Coupling of Radio Frequency (RF) energy into the body for medical hyperthermia is common

- High frequencies (microwave range) are good for focused heating of superficial/near surface tumors due to high absorption in tissue and short wavelength

- Mid-range radio frequencies (70-150MHz) penetrate to body core if used in multi-antenna phased arrays, but heat large regions (whole pelvis) due to long wavelength

- Low radio frequencies (induction heating) have good potential for treating deep seated tumors, especially using a susceptor inserted in the region where heating is desired (tumor)

- The challenge is to heat the tumor region in a controlled manner to a sufficient temperature for therapeutic effect without exposing too much healthy tissue to toxic levels of heat

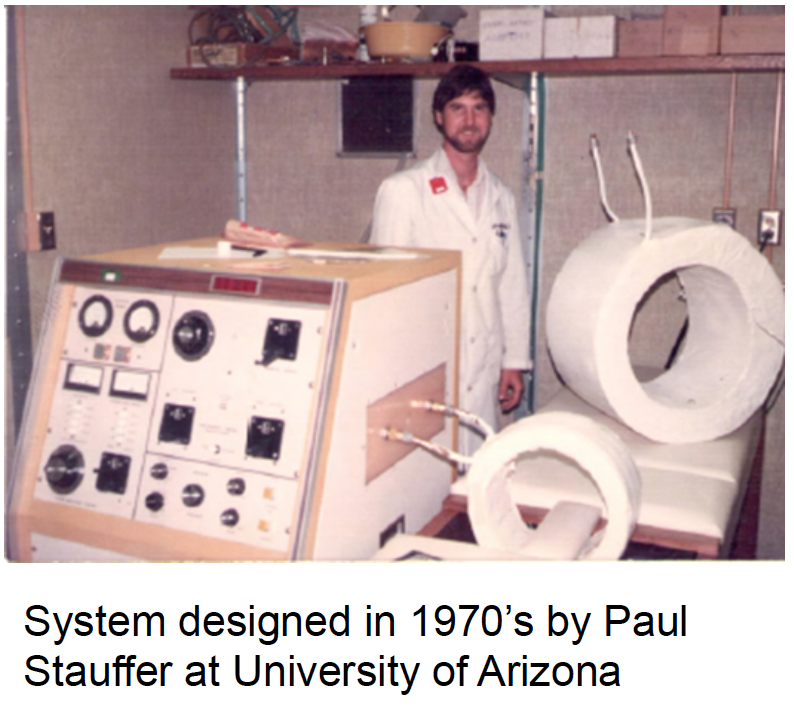

Induction Heating for Cancer Treatment using Interstitial Rods

- First human trials in the 1970’s thru early 1990’s were conducted using an array of interstitial metal needle or seed implants in the tumor for heat delivery

Clinical Trial Results

- Median survival significantly better than today's treatments for GBM in USA

- Treatment did not gain FDA approval due to some acute toxicities during the trials and high surgical effort required to implant catheter arrays

Magforce AG Magnetic Nanoparticle Hyperthermia System

- Has EU approval for treatment of GBM

- Currently available at 6 centers in Germany

- 1 System currently installed in US (Seattle, WA) with a goal of conducting a clinical trial for prostate cancer

- System produces lower survivability results compared to Ferroseed trials, but with fewer acute toxicities

- Some differences in radiation protocols and patient populations, not 100% apples to apples comparison

Comparison of Hyperthermia Trials for Brain Cancer

Background on Fluxtrol/AMF Lifesystems Activities in the Medical Field

- Fluxtrol, Inc. is a company founded in 1981 specializing in the control of alternating magnetic fields from DC to the low MHz frequency range

- Materials for magnetic flux control

- Process and Induction Coil Optimization

- Cooperative development of new technologies

- Fluxtrol began working on applications for magnetic hyperthermia in the late 1990’s.

- Heating of Interstitial Self-regulating Thermal Rods for prostate cancer with Ablation Technologies

- In 2001, Fluxtrol began working in the area of magnetic nanoparticle hyperthermia with the Triton Systems group (through several evolutions, became the technology being utilized at Dartmouth for magnetic hyperthermia)

- As activity and potential for the market increased, AMF Lifesystems (AMF) was founded as a stand alone company in 2008 to develop systems for medical therapies utilizing alternating magnetic fields

AMF Systems already Built for Cancer Research

- Magnetic field measurement at levels of clinical relevance

- SAR measurement of magnetic nanoparticles

- High Field In-Vitro testing

- High Field Small Animal In-Vivo testing

- High Field Medium Sized Animal testing

- Surface Heating Equipment Currently being Used in for treatment of naturally occurring oral melanoma in human companion animals (family dogs)

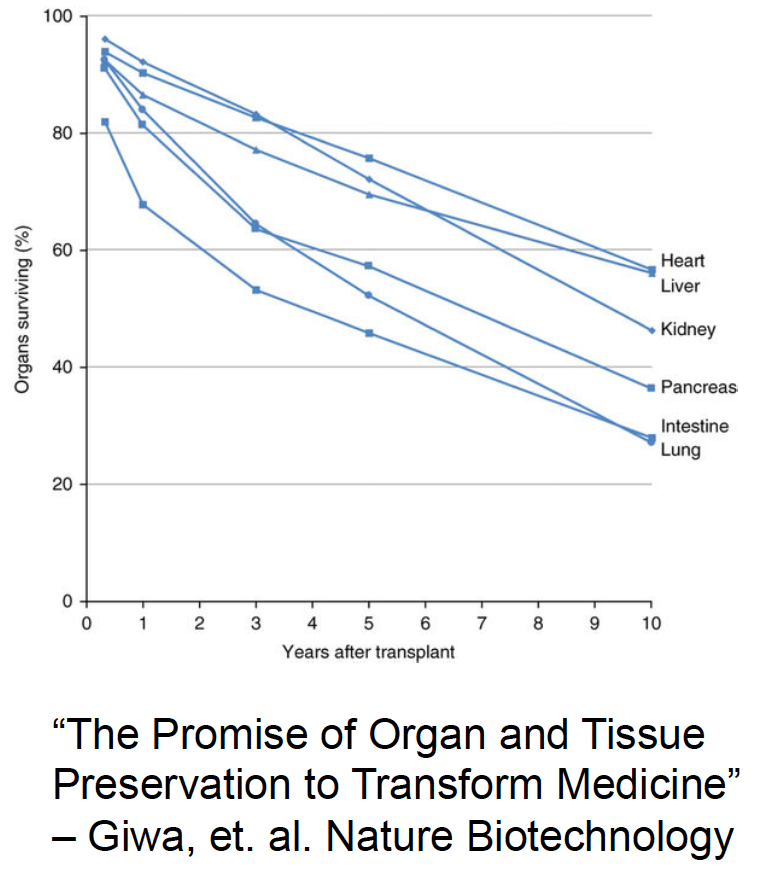

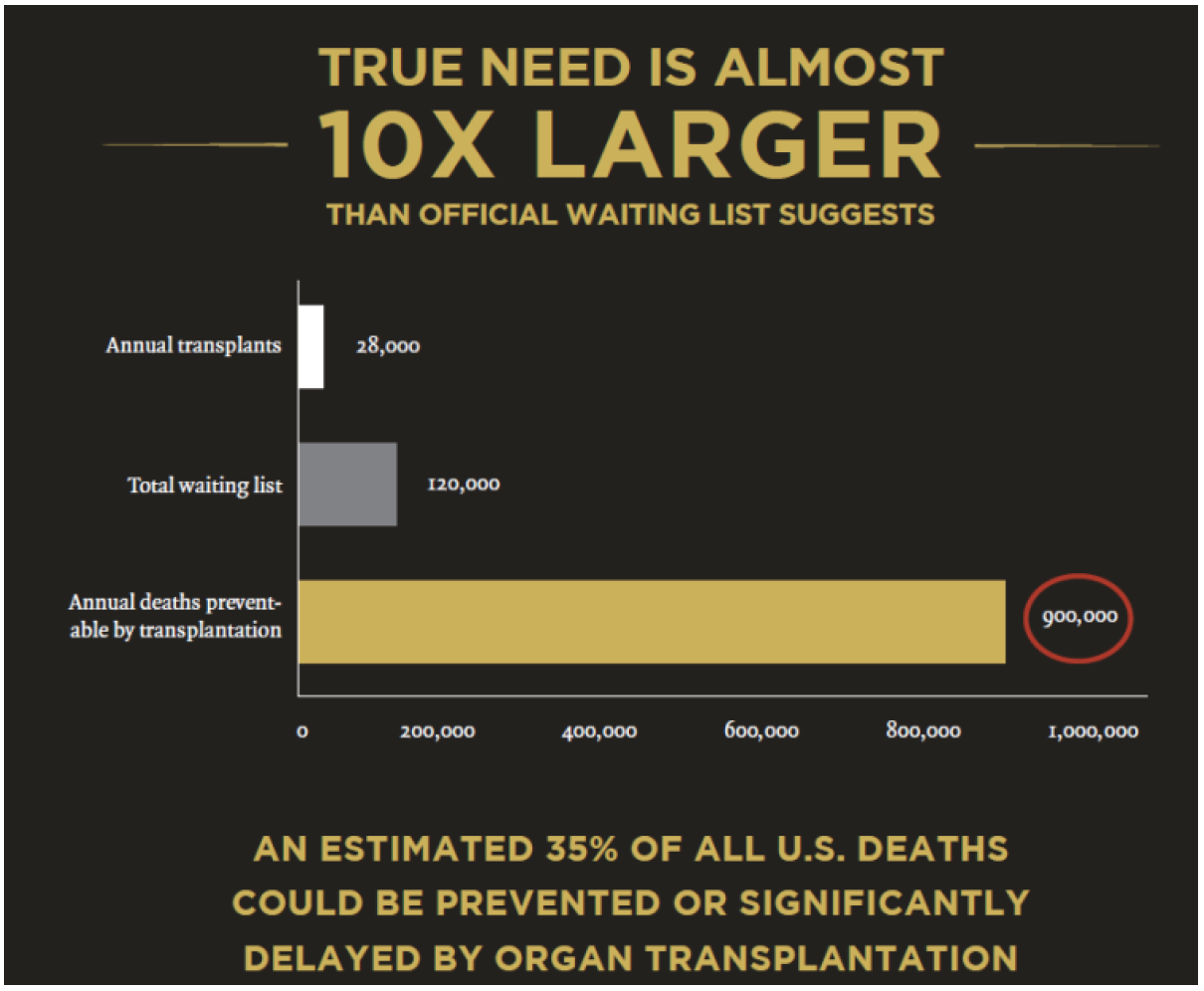

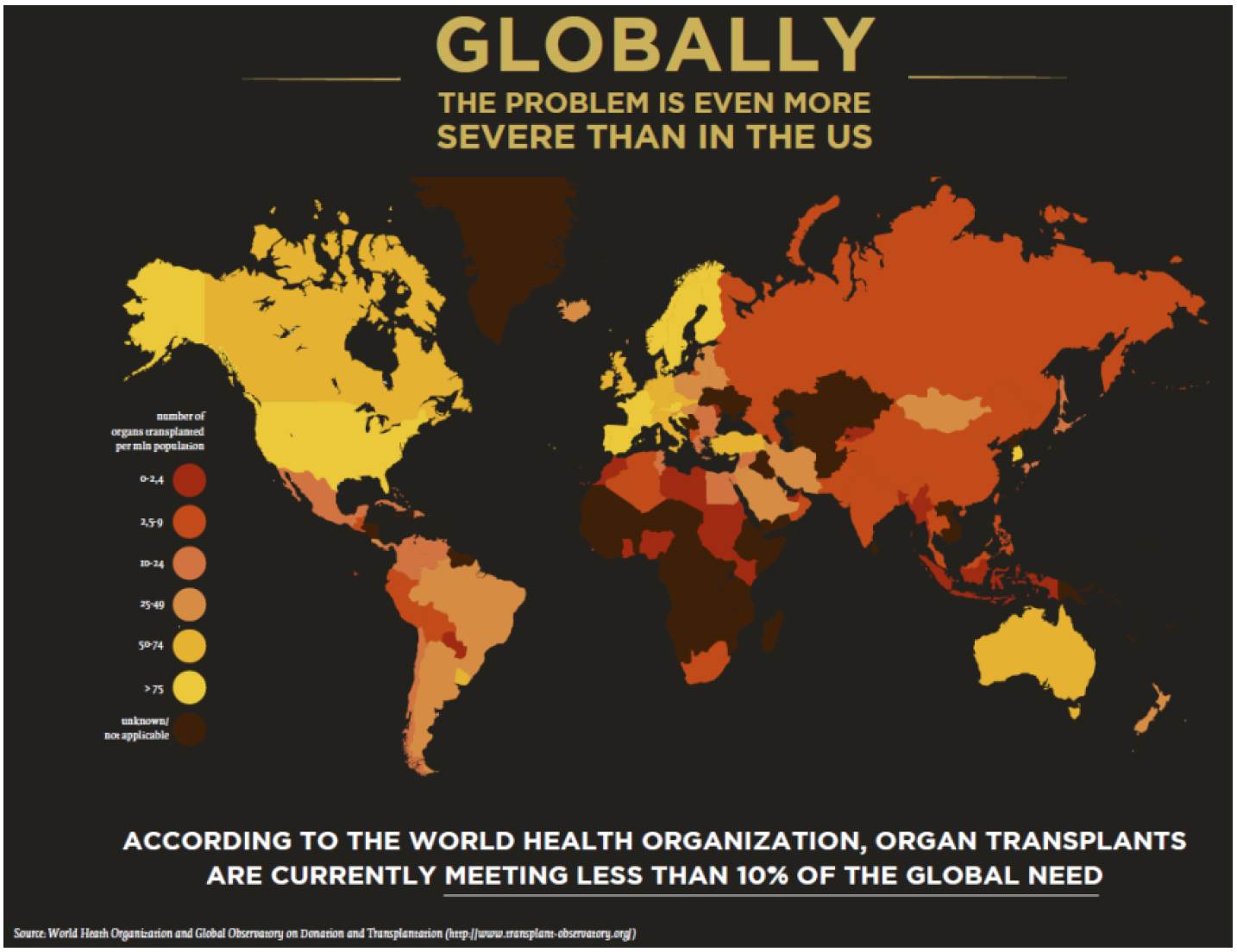

Organ Transplantation

- One of the main challenges with organ transplantation is that as soon as an organ is no longer supported by a living organism, the organ begins to rapidly degrade

- The organ can remain suitable for transplantation outside of its living biological host for a period of hours (hearts, livers, etc.) to up to around 2 days (kidneys) with standard preservation methods (placing on ice, etc.)

- This makes for significant logistical challenges, which limit the ability to find “good” matches and also drives up the cost of the process significantly

- The worse condition the organ is in upon transplantation or the lower the quality of the match, the more likely the organ recipient is to have additional complications and the shorter the lifetime of the transplant organ

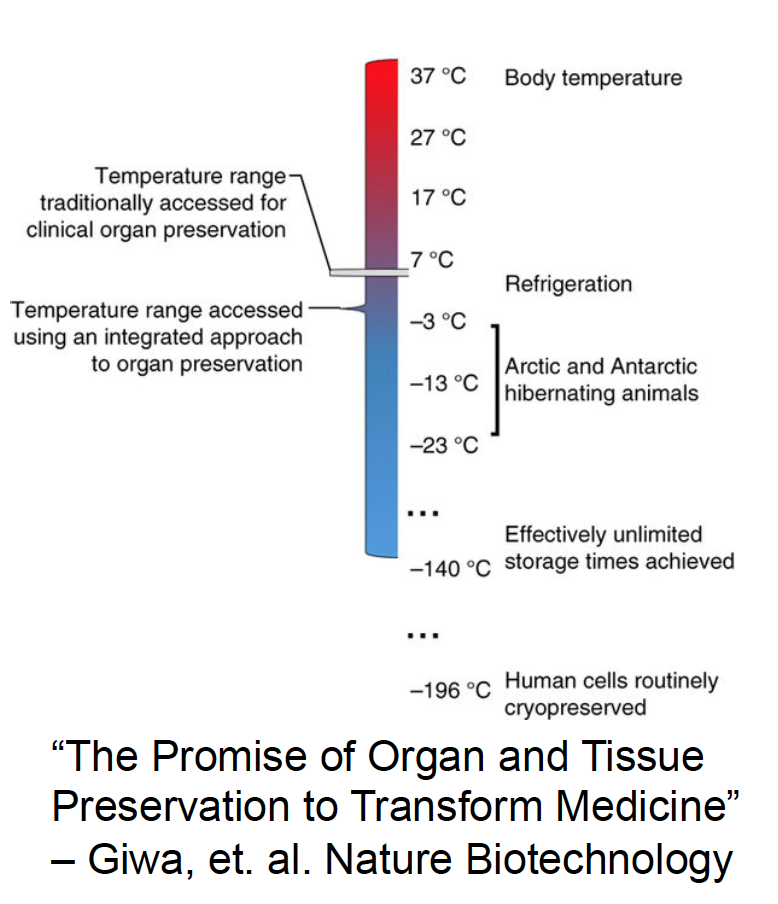

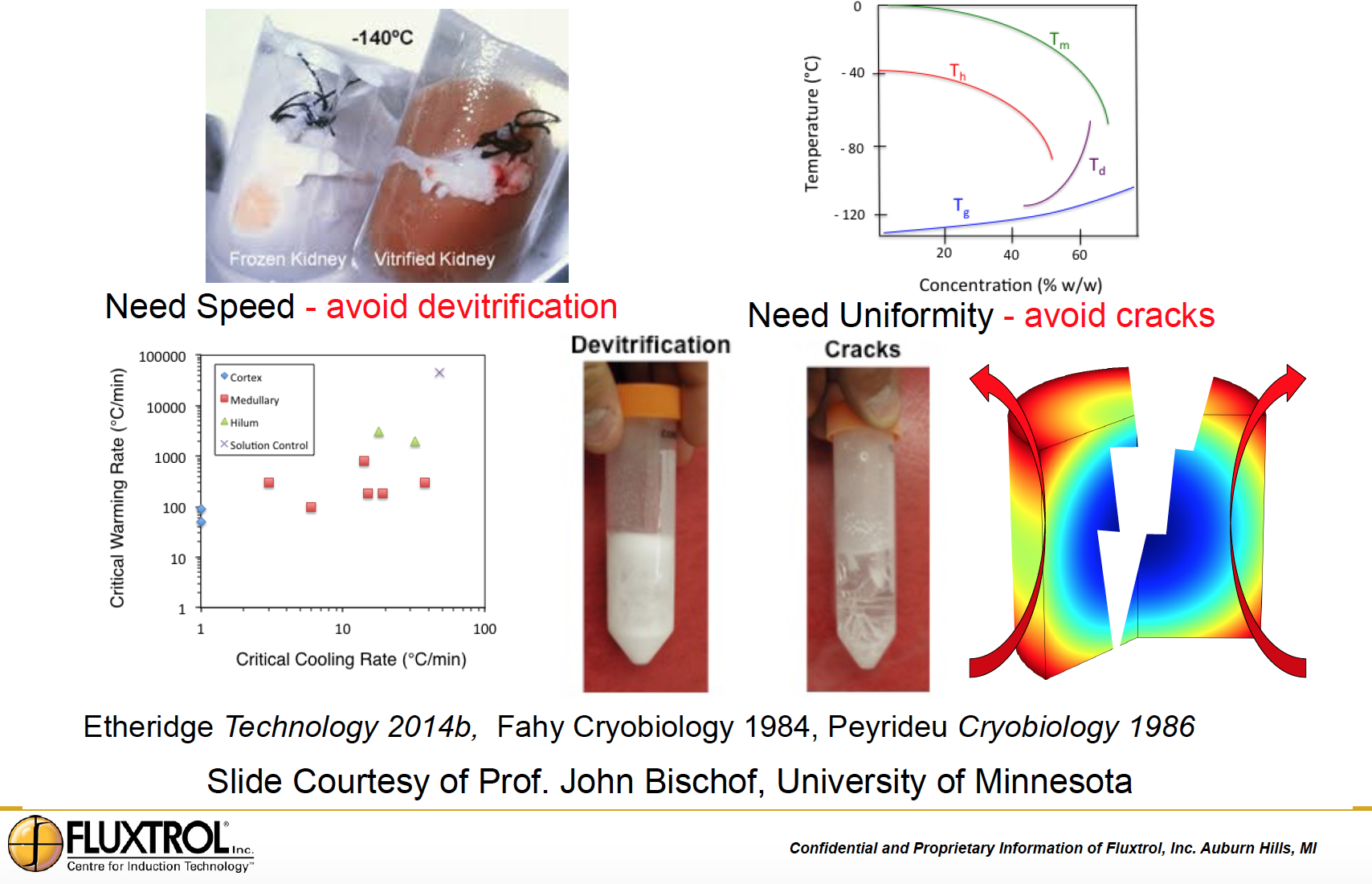

Cryopreservation of Organs

- How quickly an organ degrades is strongly dependent upon temperature

- If organs could be vitrified (T < -140C) successfully, they could be stored more or less indefinitely

Preservation in Glass: Regenerative Medicine

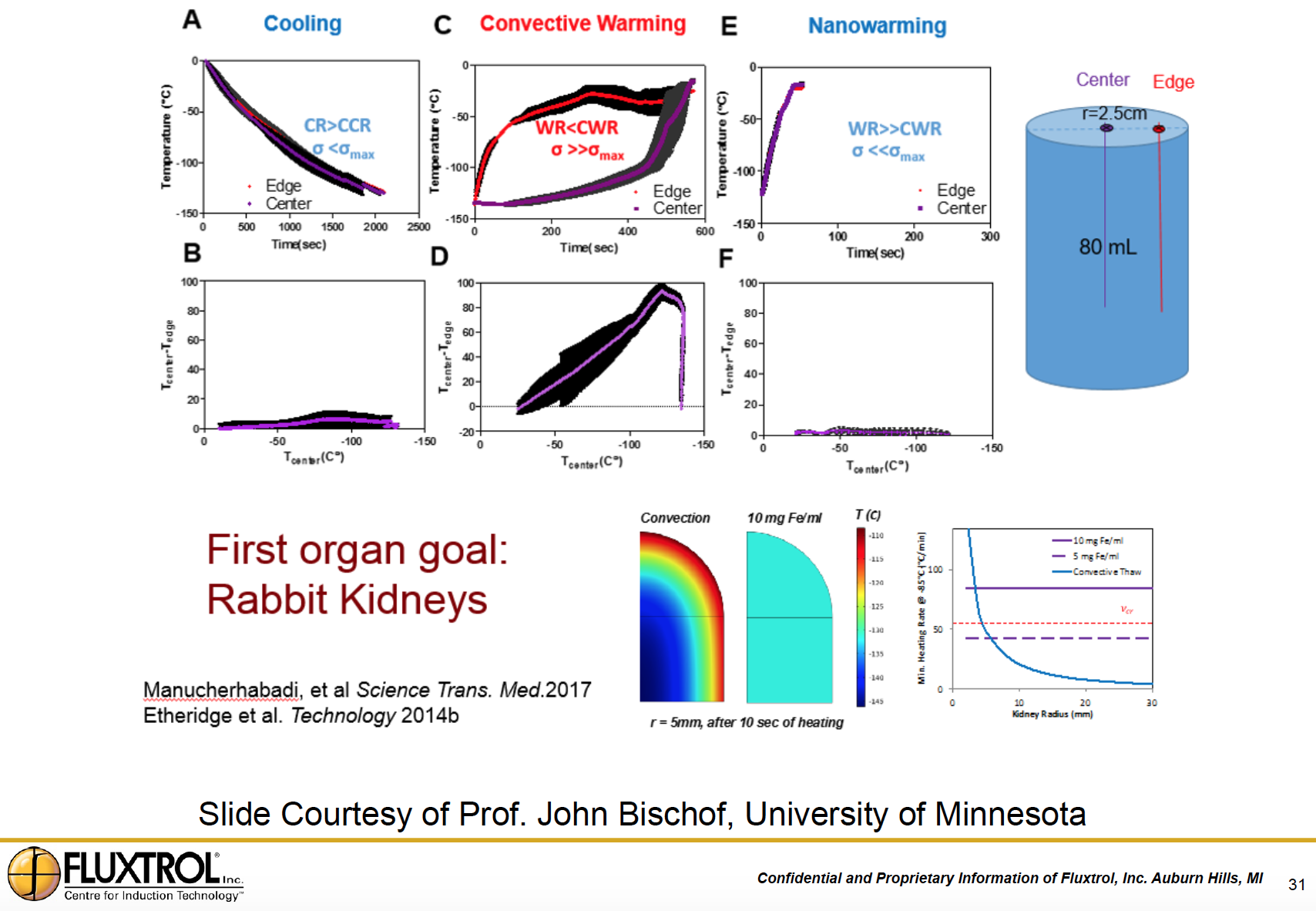

Cooling to glass works…but warming back remains a challenge

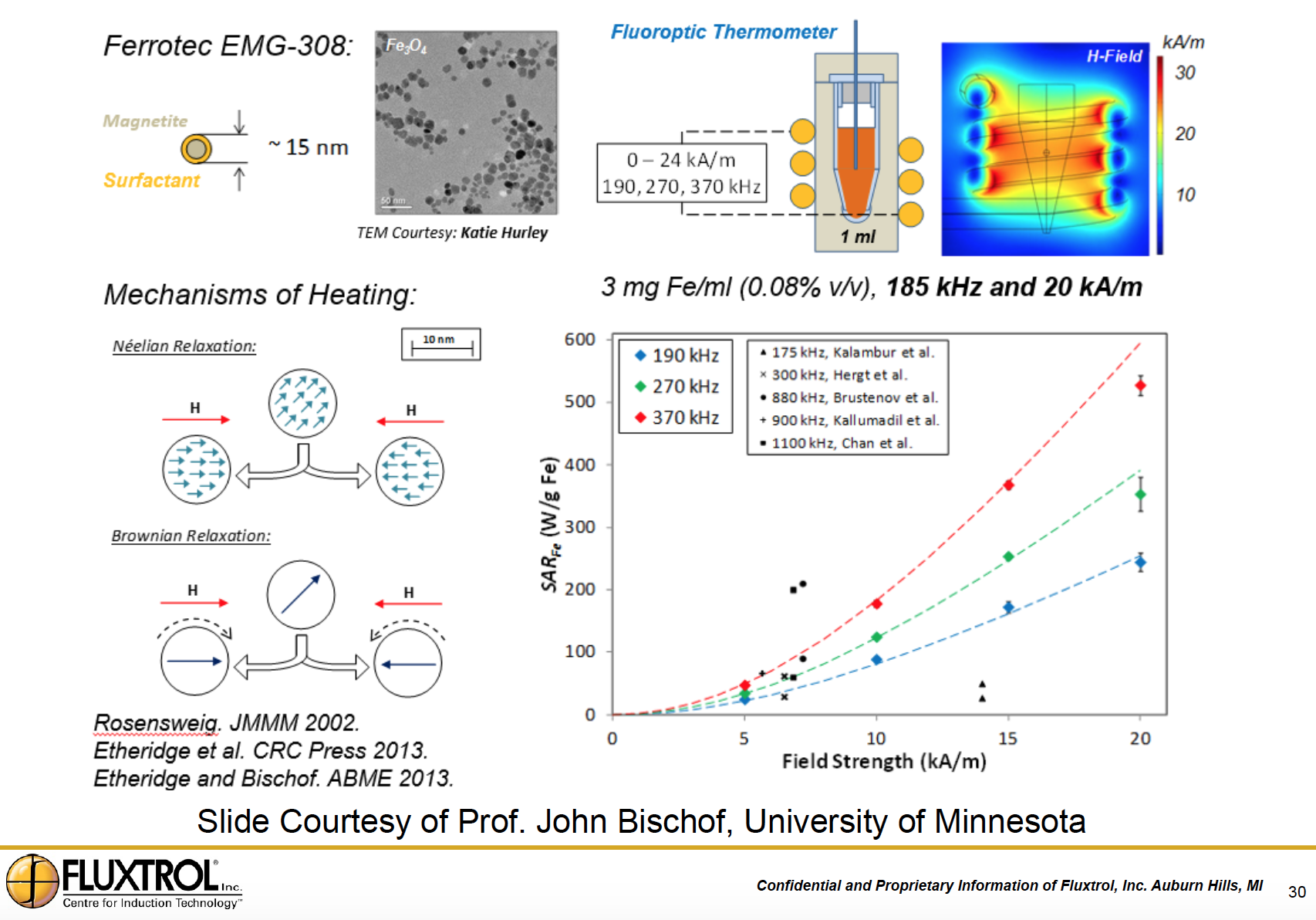

IONP Heating in RF (Alternating Magnetic) Fields

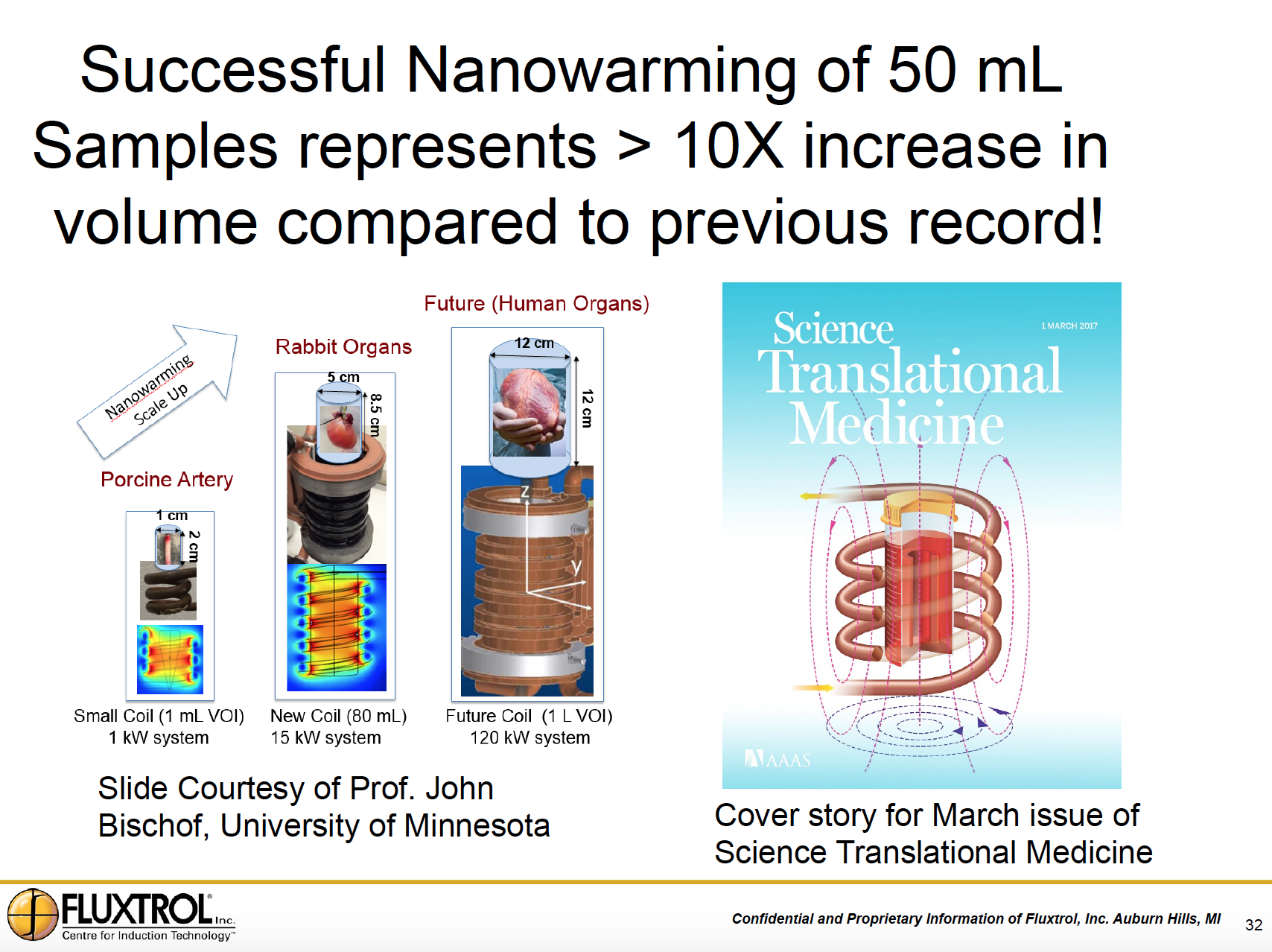

Nanowarming Scale Up

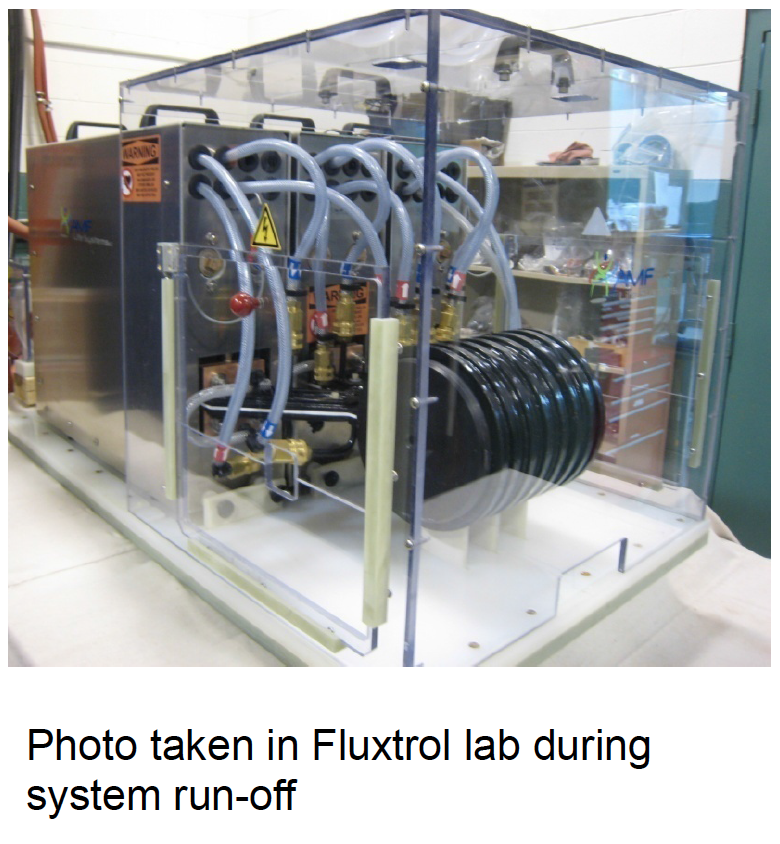

Clinical Sized AMF System

- Pilot Machine in Operation at Johns Hopkins University for Cancer Research

- Modular Remote Heat Station and Coil

- Patent Pending

- IP Behind this System Basis for System Capable of Nanowarming Large Tissues/Organs

Deep Space Exploration

Clinical Sized AMF System

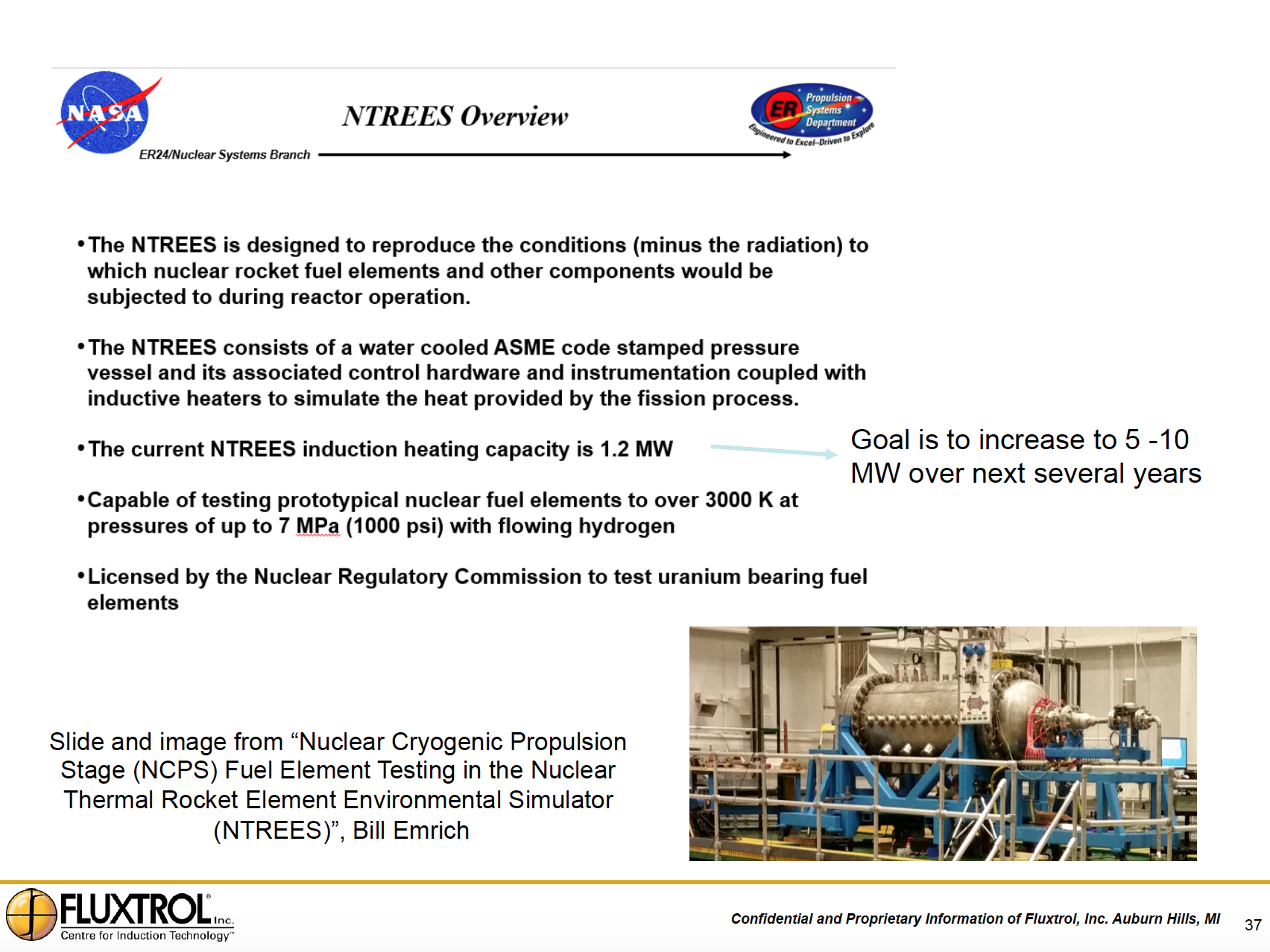

- 20 NTP engines built and tested in 1970’s.

- Testing was halted due program termination

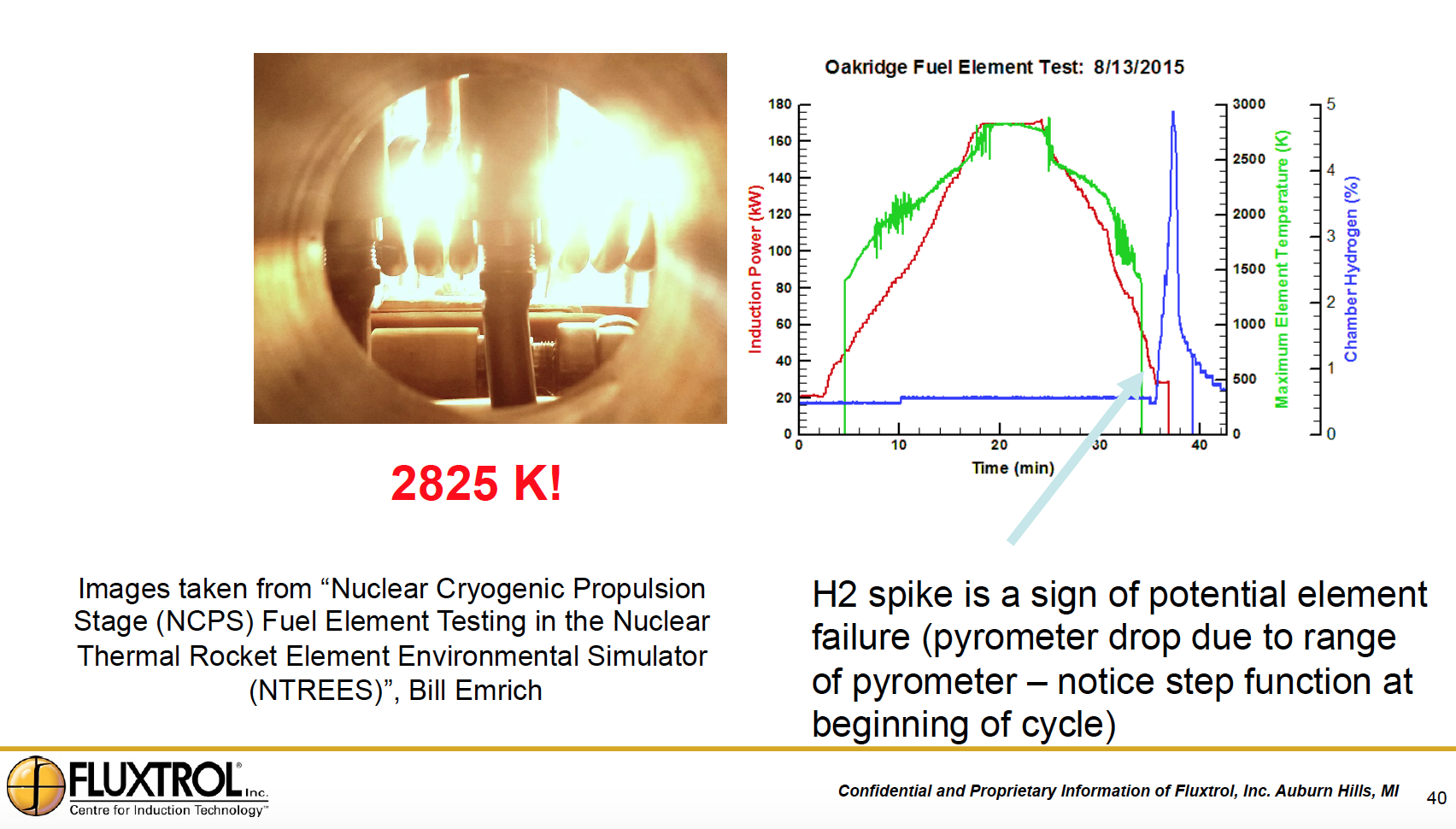

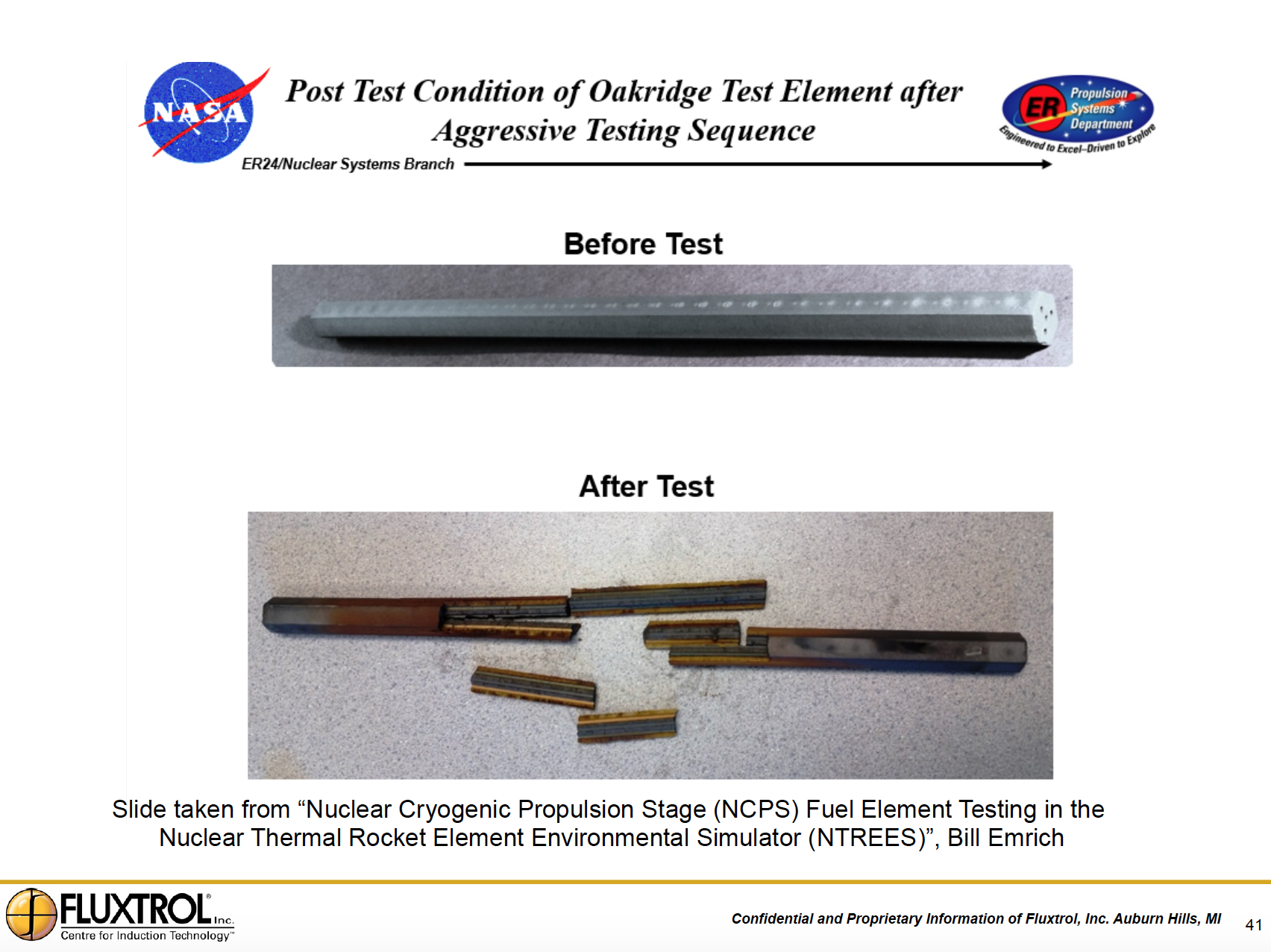

- CFEET and NTREES systems developed to test survivability of fuel elements under operating conditions without radiation lowering test costs to around $25 k

- Induction Heating is used to simulate power densities generated by nuclear reactor

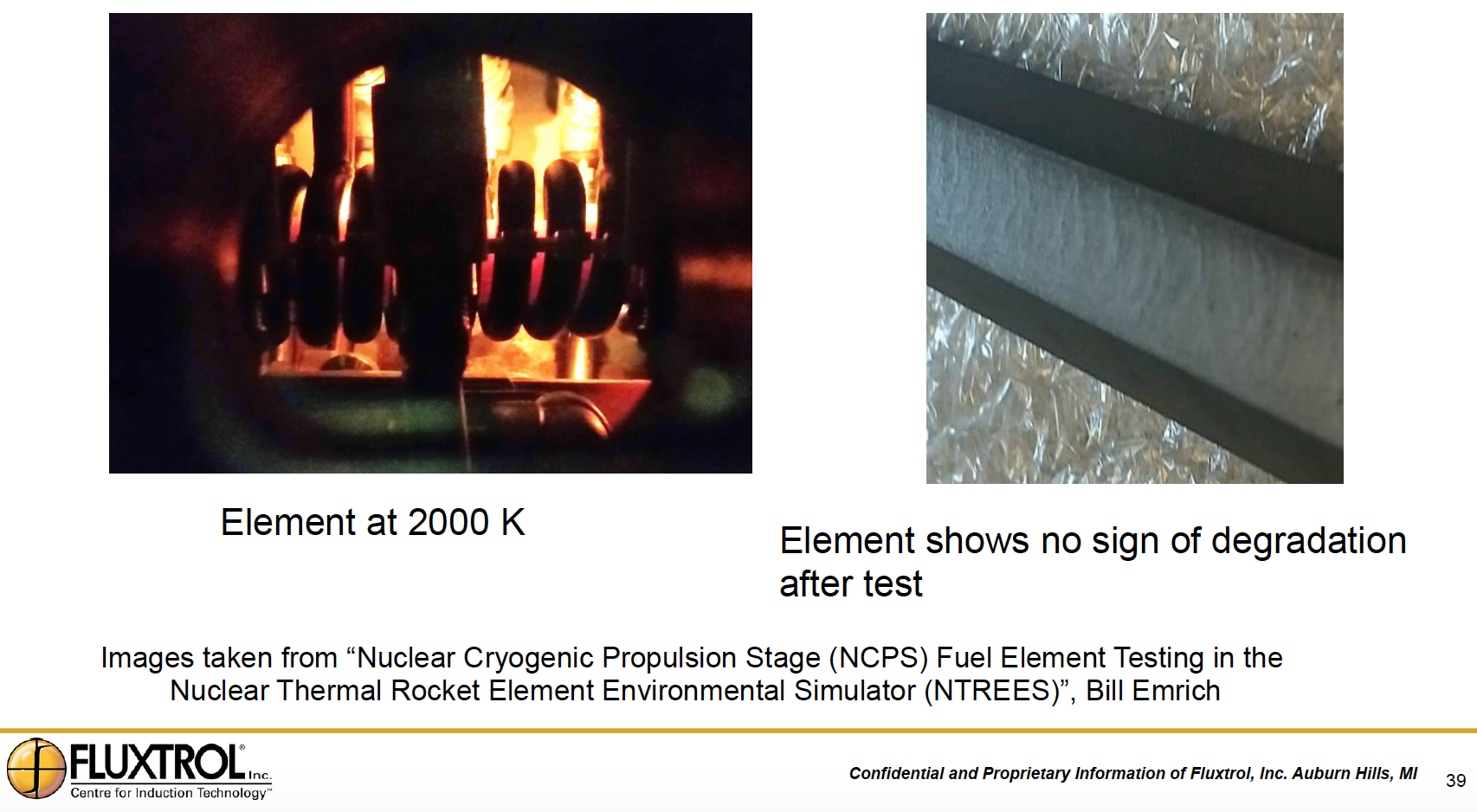

“Low” Power Testing of Fuel Element

“Medium” Power Testing

Summary

- Induction heating is a unique, environmentally friendly technology that is being utilized in a wide variety of manufacturing industries

- Induction heating is also being utilized in the development of new medical technologies that have the potential to save many lives

- Hyperthermia technology for treatment of cancer

- Nanowarming for thawing of cryopreserved organs

- Induction heating is often used for Accelerated Lifetime Testing to verify performance of components in high power density applications

- NTREES system for ensuring safe deep space exploration

Acknowledgements

- Many of the slides in this presentation were taken from the “Basics of Induction Heating Parts I & II” prepared by Dr. Valentin Nemkov (www.fluxtrol.com)

- Thanks to Prof. John Bischof for permission to use many of his slides on the nanowarming technology

- Thanks to Dr. Bill Emrich for providing the slides and videos on the NTREES system

If you have more questions, require service or just need general information, we are here to help.

Our knowledgeable Customer Service team is available during business hours to answer your questions in regard to Fluxtrol product, pricing, ordering and other information. If you have technical questions about induction heating, material properties, our engineering and educational services, please contact our experts by phone, e-mail or mail.

Fluxtrol Inc.

1388 Atlantic Boulevard,

Auburn Hills, MI 48326

Telephone: +1-800-224-5522

Outside USA: 1-248-393-2000

FAX: +1-248-393-0277