Information

Authors: Tareq Eddir (Fluxtrol Inc.), Robert C. Goldstein (Fluxtrol Inc.), Robert Haun (Anspanner LLC)

Location/Venue: UIE 2021 Pilsen, Czech Republic

Outline

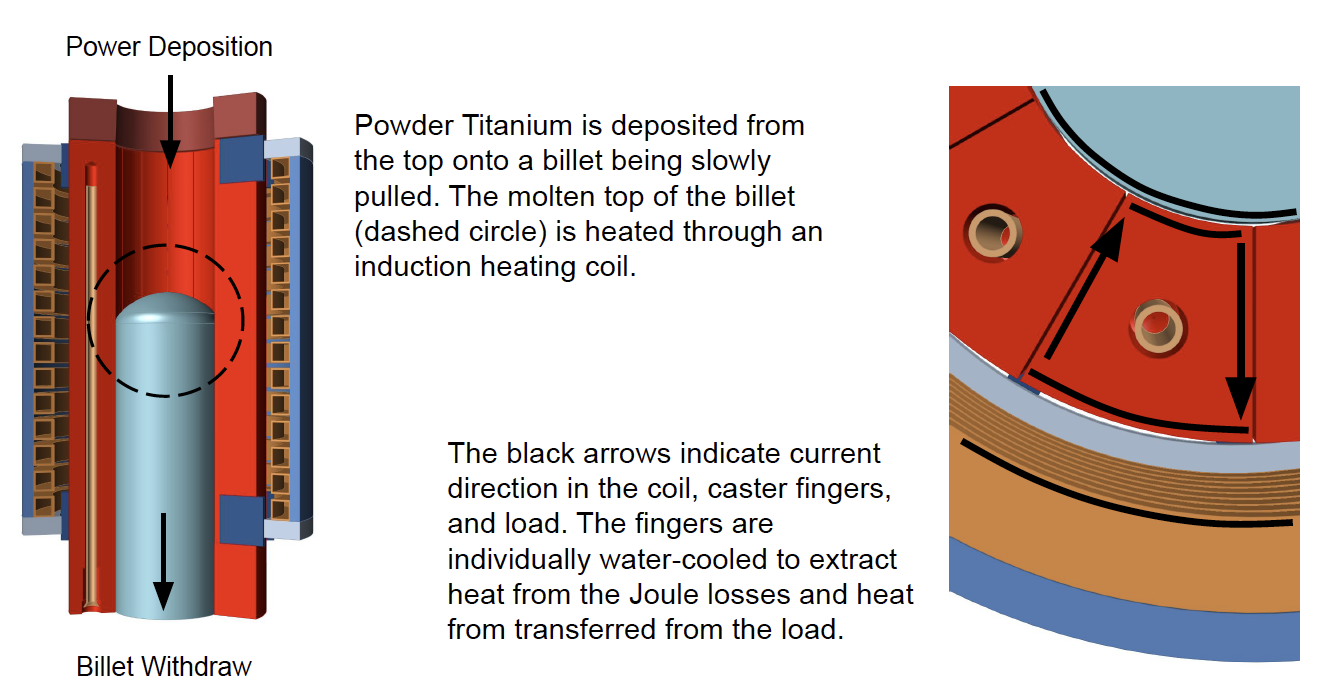

- Cold Wall Induction Billet Casters background

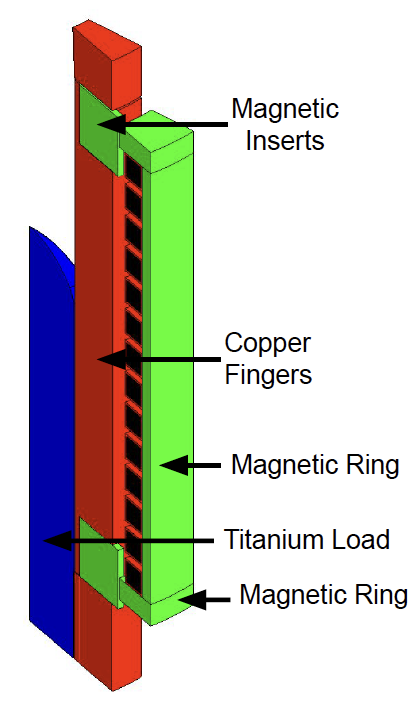

- Geometry Description

- Simulation Description

- Electrical Parameter Results

- Current Density Results

- Conclusions

Background

- Titanium powder production has increased substantially for additive manufacturing and the aerospace industry

- Powder is manufactured via techniques such as EIGA, which results in a relatively non-uniform powder size

- Additive manufacturing of titanium parts requires uniform powder sizes, resulting in low yields of acceptable powder sizes

- Rejected powder is recycled through cold wall billet casters

- The cold wall design results in low electrical efficiency

- Soft magnetic composites have shown to increase efficiency of cold crucibles and may help reduce power demand in billet casters as well

Geometry Description

Simulation Description

Flux 3D FEM software was used for the simulation

- 3D geometry was used

- Electromagnetic physics was used

- 1000ARMS at 5 kHz was used for all simulations

- Load resistivity of 1.7 µΩm was used

- Fluxtrol 100 soft magnetic composite was used for the magnetic inserts, rings, and shunts

- 1/24th of the geometry was modelled using symmetry planes

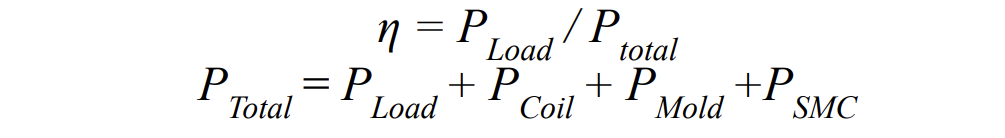

Electrical Results

| Case | U | PLoad | PCoil | PMold | PSMC | η |

| Bare | 7.9 | 368 | 280 | 612 | 0 | 29.2% |

| Inserts | 9.1 | 634 | 268 | 647 | 4 | 40.8% |

| Rings and Inserts | 9.8 | 714 | 279 | 733 | 7.7 | 41.2% |

| Rings and Shunts | 9.4 | 435 | 316 | 771 | 29 | 28.0% |

| Rings, Shunts, and Inserts | 11.1 | 824 | 328 | 872 | 47 | 39.8% |

Where:

- η is efficiency

- U is potential in V

- P is power in W

- SMC is Soft Magnetic Composite (Rings, Inserts, and Shunts)

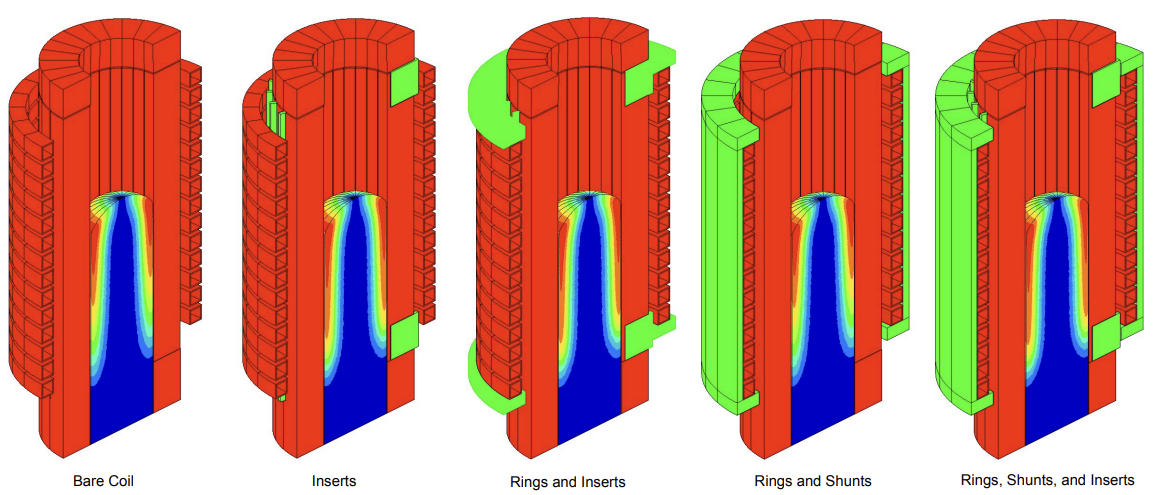

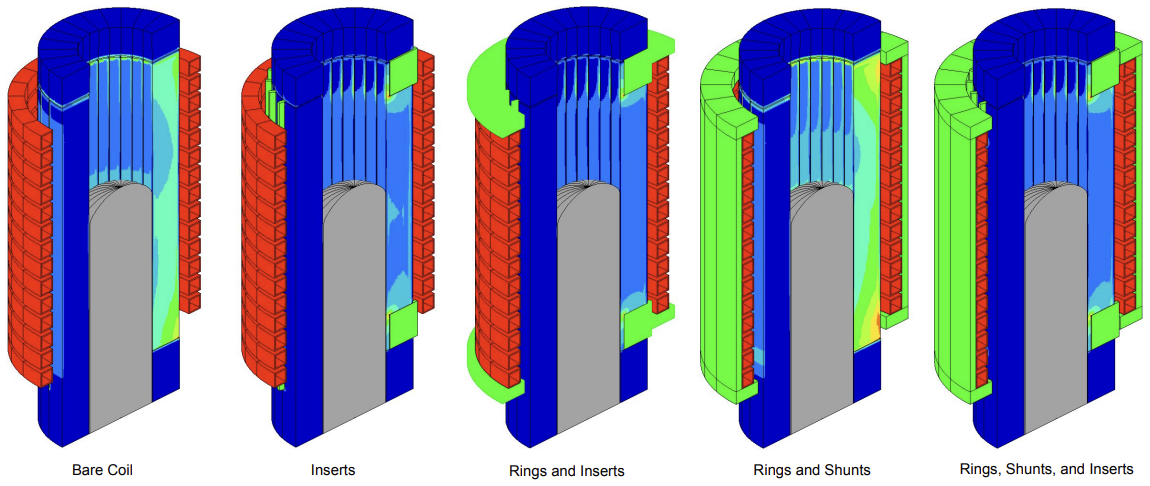

Load Current Density Contour

Mold Current Density Contour

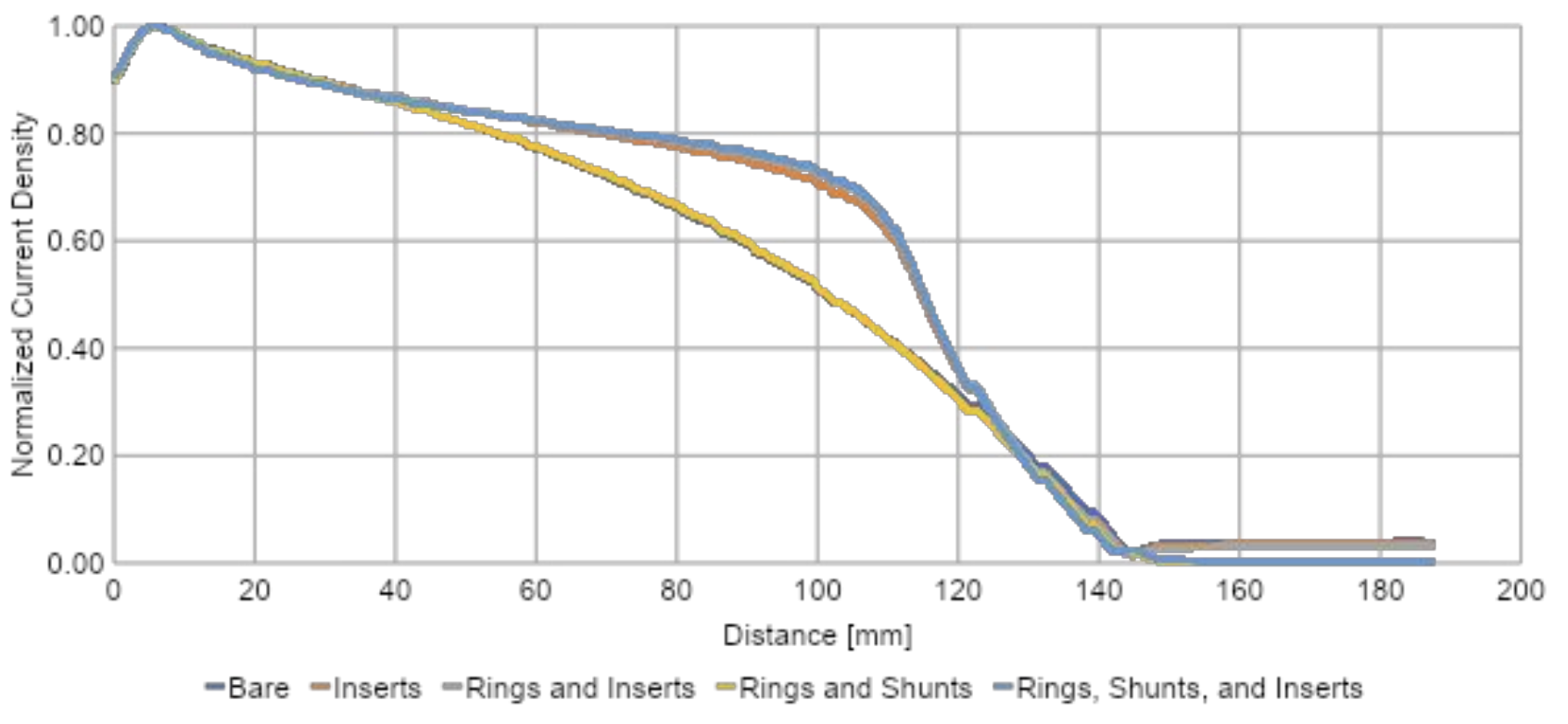

Normalized Current Density Graphs

Conclusions

- 3D simulations were made to predict the electrical parameters of different cases

- The results show using soft magnetic composites for cold wall billet casters

increases the electrical efficiency

- Adding rings and shuts on the coil showed no benefit on the efficiency

- When considering chamber heating and size, rings and shunts can be beneficial

- Addition of inserts to the billet caster increases efficiency by ~10%

- Adding rings and shuts on the coil showed no benefit on the efficiency

- An existing mold design was considered, further improvements may be achieved with an optimized design

If you have more questions, require service or just need general information, we are here to help.

Our knowledgeable Customer Service team is available during business hours to answer your questions in regard to Fluxtrol product, pricing, ordering and other information. If you have technical questions about induction heating, material properties, our engineering and educational services, please contact our experts by phone, e-mail or mail.

Fluxtrol Inc.

1388 Atlantic Boulevard,

Auburn Hills, MI 48326

Telephone: +1-800-224-5522

Outside USA: 1-248-393-2000

FAX: +1-248-393-0277